How to Choose the Right 6 Pin Rectangular Connector for Your Project

How to Choose the Right 6 Pin Rectangular Connector for Your Project Table of Contents Understanding 6 Pin Rectangular Connectors Key Factors to Consider Types of 6 Pin Rectangular Connectors Applications of 6 Pin Rectangular Connectors Technical Specifications Connector Materials Installation Tips for 6 Pin Rectangular Connectors Troubleshooting Common Issues FAQs About 6 P

How to Choose the Right 6 Pin Rectangular Connector for Your Project

Table of Contents

- Understanding 6 Pin Rectangular Connectors

- Key Factors to Consider

- Types of 6 Pin Rectangular Connectors

- Applications of 6 Pin Rectangular Connectors

- Technical Specifications

- Connector Materials

- Installation Tips for 6 Pin Rectangular Connectors

- Troubleshooting Common Issues

- FAQs About 6 Pin Rectangular Connectors

- Conclusion

Understanding 6 Pin Rectangular Connectors

6 pin rectangular connectors are widely used in various electrical applications, providing a reliable means of connecting circuitry. These connectors typically consist of a housing that can accommodate six pins, allowing for multiple electrical connections in a compact space. Their rectangular shape offers ease of alignment and mounting, making them a preferred choice for many projects in the electrical and electronics industry.

The design of these connectors caters to diverse applications, from consumer electronics to industrial machinery. Understanding their structure and functionality is crucial for selecting the right connector for specific needs.

Key Factors to Consider

When choosing the right 6 pin rectangular connector, several key factors must be evaluated:

1. Electrical Specifications

The electrical specifications of the connector include voltage rating, current rating, and resistance. Selecting a connector that meets or exceeds your project's electrical requirements is essential for performance and safety.

2. Mechanical Durability

Consider the mechanical durability of the connector, especially if it will be subject to vibration, moisture, or extreme temperatures. Check the material and design specifications to ensure it can withstand the operational demands of your application.

3. Compatibility with Other Components

Ensure the 6 pin rectangular connector is compatible with other components in your circuit. Check the pin configuration and ensure it aligns with your existing connectors or circuit boards.

4. Size and Shape

The physical dimensions of the connector matter, especially in projects with limited space. Ensure the connector's size fits well within your design constraints while providing adequate connection points.

Types of 6 Pin Rectangular Connectors

There are various types of 6 pin rectangular connectors available, each designed for specific applications:

1. Standard 6 Pin Connectors

These connectors feature a straightforward design perfect for general use. They are versatile and found in many consumer electronics.

2. Locking Connectors

Locking connectors provide additional security by ensuring a firm connection that resists accidental disconnections. These are ideal for high-vibration environments.

3. Waterproof Connectors

Waterproof connectors are designed to prevent moisture ingress, making them suitable for outdoor and harsh environments. They are essential in applications where exposure to water or humidity is a concern.

4. High-Temperature Connectors

High-temperature connectors can withstand extreme temperatures, making them suitable for applications in automotive and industrial settings.

Applications of 6 Pin Rectangular Connectors

6 pin rectangular connectors find usage in numerous applications, including:

1. Consumer Electronics

From laptops to gaming consoles, these connectors are essential in maintaining reliable connections within devices.

2. Automotive Industry

In vehicles, 6 pin connectors are used for connecting various electronic components, including sensors, lights, and control units.

3. Industrial Machinery

Industrial machinery often requires robust connectors capable of handling significant electrical loads and harsh operating conditions.

4. Telecommunications

In telecommunications equipment, these connectors are used to ensure stable and dependable connections between devices and systems.

Technical Specifications

When evaluating 6 pin rectangular connectors, pay attention to the following technical specifications:

1. Voltage and Current Ratings

Ensure the connector can handle the required voltage and current levels for your application. Typical ratings vary, but connectors often range from 3A to 15A.

2. Contact Resistance

Low contact resistance is crucial for minimizing energy loss. Aim for connectors with contact resistances typically below 10 milliohms for optimal performance.

3. Insulation Resistance

High insulation resistance prevents electrical leaks and short circuits. Look for connectors rated for at least 1000 Megaohms.

4. Temperature Range

Confirm that the connector's temperature range aligns with your project's operating conditions. Many connectors operate efficiently within -40°C to 125°C.

Connector Materials

The materials used in manufacturing 6 pin rectangular connectors impact their performance and durability. Common materials include:

1. Housing Materials

Plastic and metal are the most common housing materials. Plastic offers lightweight properties, while metal provides durability and better thermal conduction.

2. Contact Materials

Connectors typically use copper, brass, or gold-plated contacts. Gold plating enhances corrosion resistance, making it suitable for applications with challenging environmental conditions.

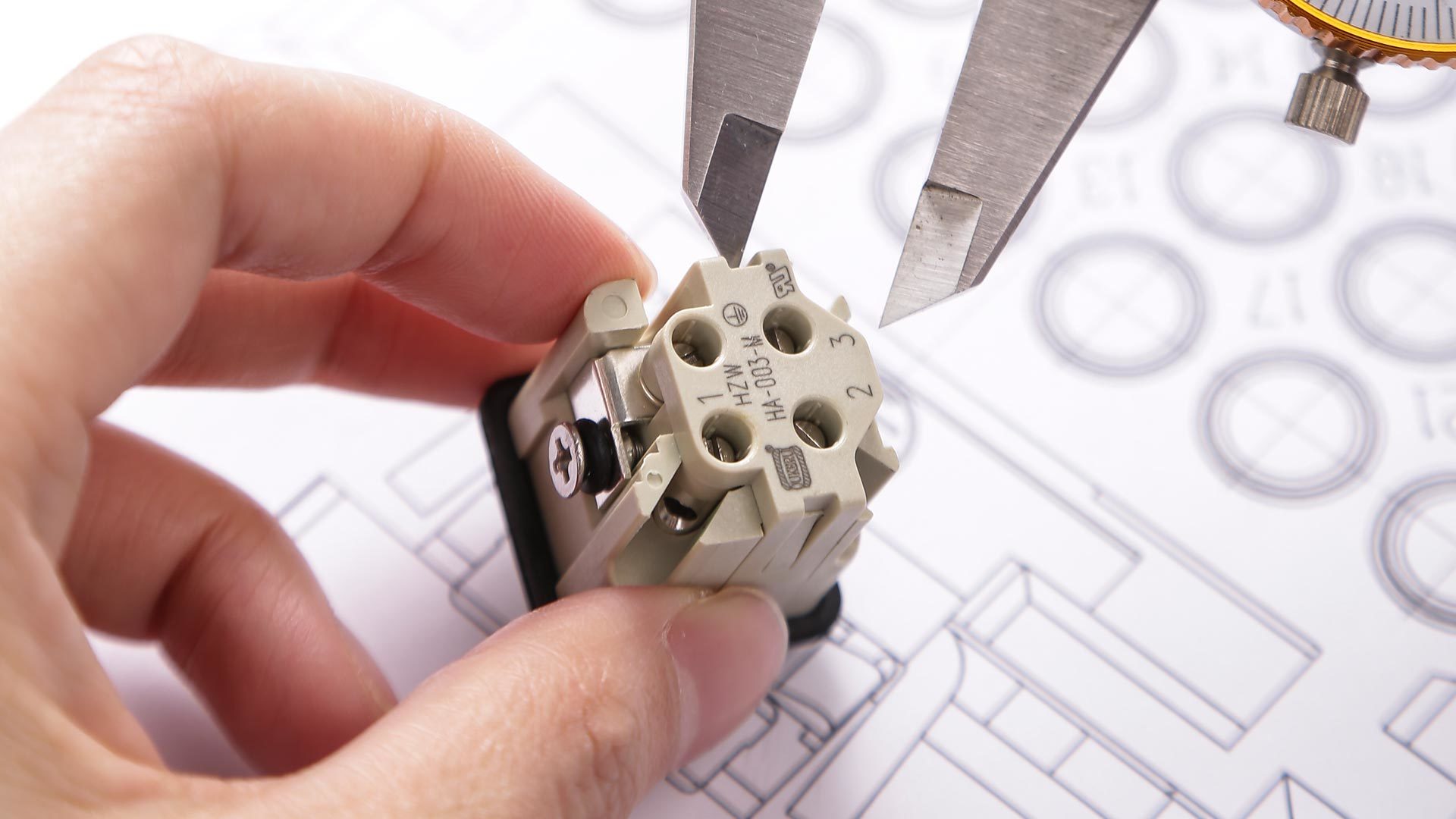

Installation Tips for 6 Pin Rectangular Connectors

Proper installation is vital for ensuring optimal performance of 6 pin rectangular connectors. Here are essential installation tips:

1. Prepare the Wires

Strip the wires carefully to avoid damages to the copper strands. Ensure appropriate wire length for a clean connection.

2. Follow the Pin Configuration

Refer to the manufacturer's pin configuration to avoid mismatches during installation. Incorrect wiring can lead to malfunction or damage.

3. Use Proper Tools

Utilize appropriate tools such as crimping tools when connecting wires to the pins. Ensuring a solid connection is critical for longevity.

4. Test Connections

After installation, perform continuity testing with a multimeter to ensure all connections are functioning correctly before powering the circuit.

Troubleshooting Common Issues

If you encounter problems with 6 pin rectangular connectors, consider these common issues:

1. Loose Connections

Ensure all connections are secure. A loose connection can cause intermittent failures.

2. Corrosion

Inspect connectors for signs of corrosion, especially in outdoor applications. Clean and replace connectors if necessary.

3. Overheating

If connectors overheat, confirm they are rated for the voltage and current they are handling. Check for any wiring faults that may cause excessive load.

4. Signal Loss

If you experience signal loss, check for proper installation and ensure the connector is suitable for your application’s specifications.

FAQs About 6 Pin Rectangular Connectors

1. What are the benefits of using a 6 pin rectangular connector?

6 pin rectangular connectors offer multiple connection points in a compact design, facilitating reliable electrical connections in various applications.

2. How do I determine the right connector for my project?

Consider electrical specifications, mechanical durability, and compatibility with other components to choose the right connector for your project.

3. Can 6 pin rectangular connectors be used in outdoor applications?

Yes, but it is essential to select waterproof connectors designed to withstand environmental factors.

4. What is the typical lifespan of a 6 pin rectangular connector?

Lifespan varies based on usage and environment, but high-quality connectors can last several years under normal operating conditions.

5. How can I prevent corrosion on connectors?

Using connectors with corrosion-resistant materials and ensuring proper sealing during installation can help reduce the risk of corrosion.

Conclusion

Choosing the right 6 pin rectangular connector for your project requires careful consideration of electrical specifications, mechanical durability, and compatibility with other components. By understanding the various types, applications, and materials available, you can ensure optimal performance in your electrical connections. Follow the installation tips and troubleshooting advice to maximize the efficiency and longevity of your connectors. With the right knowledge, you can successfully navigate the complex landscape of connectors and make informed decisions for your projects.

Related news

Introduction to the China International Industry Fair The China International Industry Fair (abbreviated as “China Industry Fair” or “Industry Fair”) is one of China's longest-running national-level industrial exhibitions bearing the “China” designation. Since its inception in 1999,

READ MORE

OUKERUI | New Products New inserts for rectangular connectors

On the basis of the original inserts, we have newly developed straight inserts and cold pressed pins to make the installation of heavy-duty connectors more convenient and more options

READ MORE

The three-day 2025 exhibition Shanghai Electronics Show (electronica China 2025) came to an end yesterday at the Shanghai New International Expo Center. As a benchmark enterprise in the field of heavy-duty connectors, Ningbo OUKERUI Connector Co., Ltd. made a stunning debut in exhibition with multiple innovative products and solutions

READ MORE