Unlocking Versatility: How 12 Pin Rectangular Connectors Revolutionize Electrical Applications

Unlocking Versatility: How 12 Pin Rectangular Connectors Revolutionize Electrical Applications Table of Contents Introduction to 12 Pin Rectangular Connectors What Are 12 Pin Rectangular Connectors? Key Features and Advantages of 12 Pin Connectors Applications in Various Industries Design and Manufacturing Considerations Installation and Maintenance Tips Future Trends

Unlocking Versatility: How 12 Pin Rectangular Connectors Revolutionize Electrical Applications

Table of Contents

- Introduction to 12 Pin Rectangular Connectors

- What Are 12 Pin Rectangular Connectors?

- Key Features and Advantages of 12 Pin Connectors

- Applications in Various Industries

- Design and Manufacturing Considerations

- Installation and Maintenance Tips

- Future Trends in Connector Technology

- Conclusion

- Frequently Asked Questions (FAQs)

Introduction to 12 Pin Rectangular Connectors

12 pin rectangular connectors have emerged as pivotal components in the realm of electrical applications. Designed to facilitate secure and efficient connections, these connectors are revolutionizing the way we approach electrical connectivity. Their versatility enables them to serve multiple sectors, ranging from automotive to telecommunications and industrial automation. In this article, we will delve into the intricacies of 12 pin rectangular connectors, exploring their features, advantages, and myriad applications.

What Are 12 Pin Rectangular Connectors?

12 pin rectangular connectors are specialized electrical connectors featuring **twelve contact points** arranged in rectangular housings. These connectors are meticulously engineered to create robust electrical connections while ensuring ease of use and reliability. The **rectangular design** not only optimizes space but also contributes to improved mechanical stability and alignment during installation.

The Importance of Pin Configuration

The **pin configuration** of 12 pin connectors is crucial for their performance. The twelve pins provide ample connectivity for various electrical circuits, enabling the transmission of power and signals simultaneously. This configuration is particularly beneficial in applications where space is at a premium, allowing manufacturers to streamline their designs without compromising functionality.

Key Features and Advantages of 12 Pin Connectors

Understanding the unique features and advantages of 12 pin rectangular connectors is essential for industries looking to enhance their electrical applications. Here are some of the standout characteristics:

1. Enhanced Durability

12 pin connectors are built to withstand harsh environmental conditions. Their robust construction, often made from high-quality materials such as thermoplastic and metal, ensures longevity and resistance against mechanical stress, temperature fluctuations, and chemical exposure.

2. Versatile Application Range

The versatility of 12 pin connectors allows them to be used across a wide array of applications, including:

- Automotive electronics

- Industrial machinery

- Telecommunications equipment

- Home appliance connections

3. Easy Installation

The design of these connectors facilitates straightforward installation. They often feature user-friendly locking mechanisms that ensure secure connections without the need for specialized tools. This ease of use can significantly reduce installation time and costs.

4. High Reliability

12 pin rectangular connectors are engineered for optimal performance, ensuring minimal signal loss and electrical resistance. Their reliable connections reduce the risk of downtime and maintenance issues, making them a preferred choice in critical applications.

5. Customizable Solutions

Many manufacturers offer customization options for 12 pin connectors, allowing clients to tailor the specifications to meet their unique needs. This adaptability is essential for industries with specific requirements or innovative designs.

Applications in Various Industries

The applications of 12 pin rectangular connectors span numerous industries. Below, we highlight some of the key sectors where these connectors play a crucial role:

1. Automotive Industry

In the automotive sector, 12 pin connectors are widely utilized for various electronic systems, including engine control units, infotainment systems, and safety features. Their reliability ensures that critical systems function seamlessly, enhancing overall vehicle performance and safety.

2. Industrial Automation

In manufacturing environments, 12 pin connectors are essential for connecting sensors, actuators, and control systems. Their ability to handle high currents and voltages makes them ideal for industrial applications where efficiency and reliability are paramount.

3. Telecommunications

Telecommunication equipment relies heavily on efficient connectivity solutions. 12 pin connectors facilitate the transmission of data and voice signals, ensuring robust performance in network infrastructure, routers, and switches.

4. Home Appliances

From washing machines to refrigerators, 12 pin connectors are integral to the functioning of home appliances. Their compact design and reliability allow for efficient connections, contributing to improved appliance performance and longevity.

5. Medical Equipment

In the medical field, precision and reliability are critical. 12 pin rectangular connectors are used in diagnostic equipment, imaging devices, and patient monitoring systems, ensuring that vital information is transmitted accurately and securely.

Design and Manufacturing Considerations

When designing and manufacturing 12 pin rectangular connectors, several factors must be taken into account to ensure optimal performance and user satisfaction.

1. Material Selection

Choosing the right materials is crucial for ensuring durability and performance. High-quality plastics and metals are often used to withstand environmental factors and mechanical stress.

2. Contact Design

The design of the contact points must ensure minimal resistance and optimal conductivity. This often involves using surface treatments and finishes that enhance electrical performance while minimizing wear and tear.

3. Temperature and Environmental Resistance

Connectors must be designed to operate under varying temperature conditions. Understanding the operational environment will guide the selection of materials and coatings that provide necessary resistance to heat, moisture, and chemicals.

4. Compliance with Standards

Adhering to industry standards and regulations is essential for manufacturing 12 pin connectors. This compliance ensures safety, reliability, and compatibility within various electrical systems.

Installation and Maintenance Tips

Proper installation and maintenance are vital for maximizing the longevity and performance of 12 pin rectangular connectors. Here are some essential tips:

1. Follow Manufacturer Guidelines

Adhering to the manufacturer’s specifications during installation is crucial. This includes following torque settings, connection procedures, and ensuring proper alignment.

2. Regular Inspections

Routine inspections help identify signs of wear, corrosion, or damage. Addressing these issues promptly can prevent costly downtime and maintenance.

3. Proper Cleaning Techniques

Maintaining cleanliness around the connectors ensures optimal performance. Use appropriate cleaning solutions and methods to avoid damaging the contacts.

4. Avoid Overloading

Ensure that the connectors are not subjected to loads beyond their rated capacity. Overloading can lead to overheating and premature failure.

Future Trends in Connector Technology

As technology continues to evolve, the connector industry is also experiencing significant advancements. Here are some emerging trends to watch:

1. Increased Miniaturization

As devices become smaller and more compact, the demand for miniature connectors is on the rise. 12 pin rectangular connectors are adapting to these changes, offering smaller footprints without sacrificing performance.

2. Smart Connectors

With the rise of the Internet of Things (IoT), smart connectors equipped with sensors and communication capabilities are becoming more prevalent. These connectors can monitor performance and provide data analytics for improved functionality.

3. Enhanced Materials and Coatings

Innovations in materials science are leading to the development of connectors that offer better performance in extreme environments. Advanced coatings can improve corrosion resistance and conductivity.

4. Sustainability Initiatives

As industries focus on reducing their environmental impact, manufacturers are exploring sustainable practices in connector production. This includes using recyclable materials and reducing waste during manufacturing processes.

Conclusion

12 pin rectangular connectors are revolutionizing the electrical landscape, offering unmatched versatility and reliability across diverse applications. Their robust design, ease of use, and adaptability make them indispensable in various industries. As technology continues to advance, these connectors will likely evolve, contributing to even greater efficiencies and innovations in electrical applications. By embracing the potential of 12 pin rectangular connectors, industries can enhance their operational performance and pave the way for future advancements.

Frequently Asked Questions (FAQs)

1. What is the primary advantage of using 12 pin rectangular connectors?

The primary advantage is their ability to provide secure, reliable connections in a compact format, making them suitable for various applications across industries.

2. Are 12 pin connectors customizable?

Yes, many manufacturers offer customization options to meet specific needs, including pin arrangements, materials, and coatings.

3. Can 12 pin connectors be used in outdoor applications?

Yes, when designed with appropriate materials and coatings, 12 pin connectors can withstand outdoor conditions and are suitable for various applications.

4. How do I ensure proper installation of 12 pin connectors?

Always follow the manufacturer's installation guidelines, ensuring proper alignment and torque settings to guarantee a secure connection.

5. What industries commonly use 12 pin rectangular connectors?

They are widely used in industries such as automotive, industrial automation, telecommunications, home appliances, and medical equipment.

Related news

Introduction to the China International Industry Fair The China International Industry Fair (abbreviated as “China Industry Fair” or “Industry Fair”) is one of China's longest-running national-level industrial exhibitions bearing the “China” designation. Since its inception in 1999,

READ MORE

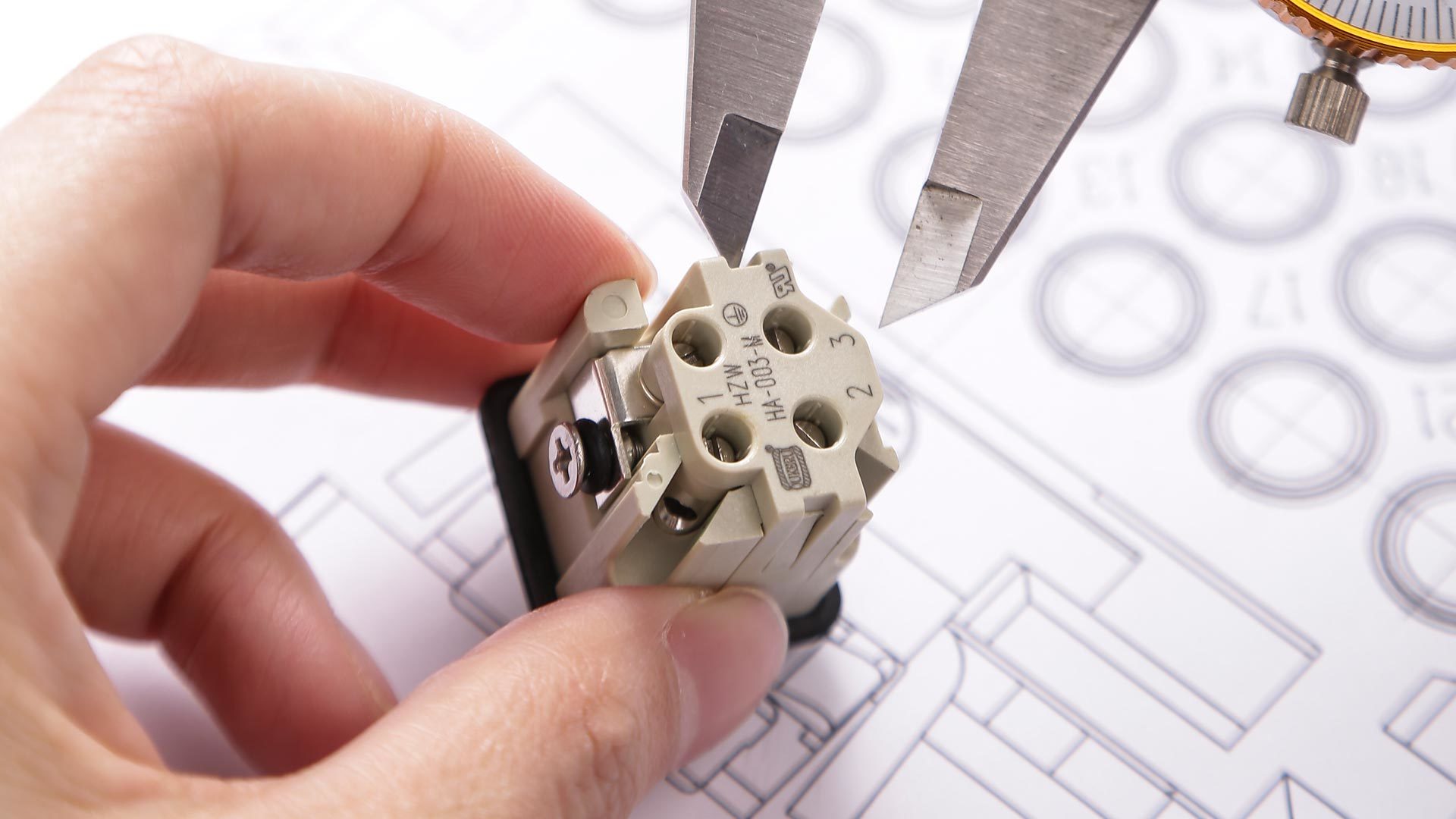

OUKERUI | New Products New inserts for rectangular connectors

On the basis of the original inserts, we have newly developed straight inserts and cold pressed pins to make the installation of heavy-duty connectors more convenient and more options

READ MORE

The three-day 2025 exhibition Shanghai Electronics Show (electronica China 2025) came to an end yesterday at the Shanghai New International Expo Center. As a benchmark enterprise in the field of heavy-duty connectors, Ningbo OUKERUI Connector Co., Ltd. made a stunning debut in exhibition with multiple innovative products and solutions

READ MORE