The Ultimate Guide to Choosing the Right HDC Connector for Your Project

The Ultimate Guide to Choosing the Right HDC Connector for Your Project Table of Contents 1. Introduction to HDC Connectors 2. Understanding HDC Connectors 3. Types of HDC Connectors 4. Key Specifications to Consider 5. Application Scenarios for HDC Connectors 6. Installation Best Practices 7. Troubleshooting Common Issues 8. Conclusion 9. Frequently Asked Questions 1. Introduction to HDC Connec

The Ultimate Guide to Choosing the Right HDC Connector for Your Project

Table of Contents

- 1. Introduction to HDC Connectors

- 2. Understanding HDC Connectors

- 3. Types of HDC Connectors

- 4. Key Specifications to Consider

- 5. Application Scenarios for HDC Connectors

- 6. Installation Best Practices

- 7. Troubleshooting Common Issues

- 8. Conclusion

- 9. Frequently Asked Questions

1. Introduction to HDC Connectors

In the realm of electrical engineering, **high-density connectors (HDC)** play a crucial role in ensuring reliable connections in various applications. Whether in industrial automation, telecommunications, or consumer electronics, choosing the right HDC connector is vital for the success of your project. This guide will dive deep into the nuances of HDC connectors, providing a detailed roadmap to help you make informed choices tailored to your specific needs.

2. Understanding HDC Connectors

HDC connectors are designed to accommodate a high number of electrical contacts within a compact space. They are engineered to support robust electrical and mechanical performance in demanding environments. By understanding the fundamental characteristics of HDC connectors, you can better appreciate their significance in various applications.

What Makes HDC Connectors Unique?

HDC connectors are often characterized by their **high pin density**, durability, and resistance to environmental factors such as moisture, dust, and temperature fluctuations. These features make them ideal for applications where space is limited but reliability cannot be compromised.

3. Types of HDC Connectors

Selecting the appropriate type of HDC connector is essential for ensuring compatibility and performance. Here are some common types of HDC connectors:

3.1. Rectangular Connectors

Rectangular HDC connectors are popular in industrial applications due to their efficiency in space utilization and ease of installation. They often feature locking mechanisms that enhance connection security.

3.2. Circular Connectors

Circular HDC connectors are commonly used in applications requiring a robust connection that can withstand harsh environments. They provide excellent resistance to vibration and environmental factors.

3.3. Modular Connectors

Modular HDC connectors offer versatility, allowing users to configure the pin arrangement to suit specific requirements. This flexibility makes them suitable for a wide range of applications.

4. Key Specifications to Consider

When choosing HDC connectors, several specifications should be taken into account to ensure optimal performance. These include:

4.1. Contact Rating

The contact rating indicates the maximum current and voltage the connector can handle. It is crucial to select a connector that meets or exceeds the requirements of your application.

4.2. Temperature Range

Different applications may expose connectors to varying temperature extremes. Ensure the selected HDC connector can operate effectively within the required temperature range.

4.3. Locking Mechanism

A reliable locking mechanism is essential for maintaining a secure connection, particularly in applications subject to movement or vibration. Evaluate the locking options available for your chosen connector.

5. Application Scenarios for HDC Connectors

HDC connectors are versatile and find applications across numerous industries. Here are some common scenarios where HDC connectors excel:

5.1. Industrial Automation

In industrial settings, HDC connectors are utilized for connecting control systems, sensors, and actuators. Their rugged design ensures stable connections even in challenging environments.

5.2. Telecommunications

HDC connectors are critical in telecommunications equipment, facilitating reliable data transmission in various networking devices.

5.3. Automotive

The automotive industry employs HDC connectors in various electronic systems, including engine management and infotainment systems, ensuring high performance and reliability.

6. Installation Best Practices

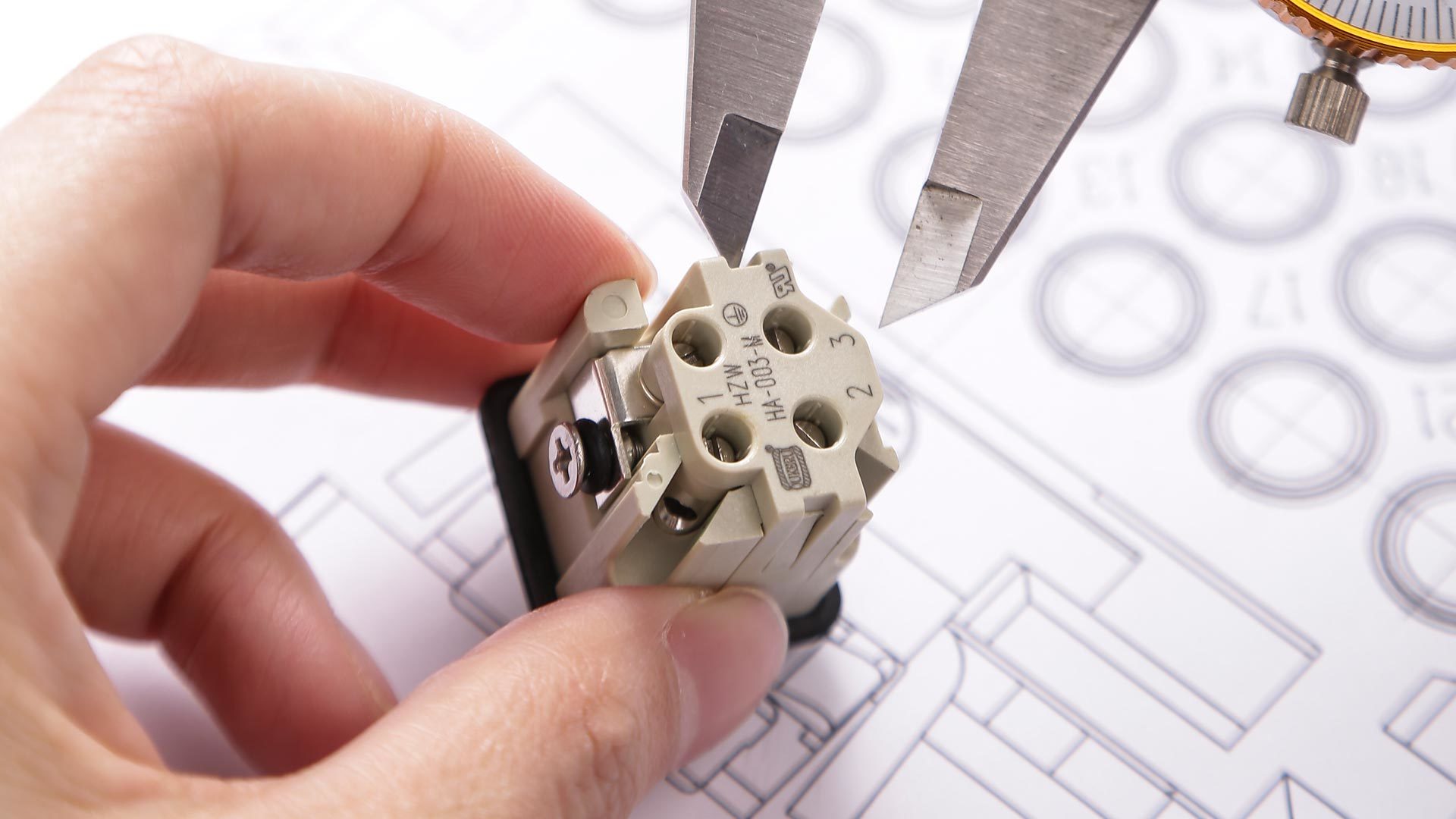

Proper installation of HDC connectors is crucial for achieving optimal performance and longevity. Follow these best practices:

6.1. Cleanliness is Key

Ensure all surfaces are clean and free from contaminants before installation. Dirt or moisture can compromise the connection quality.

6.2. Proper Torque Specifications

Follow the manufacturer's recommended torque specifications to avoid over-tightening, which can damage connectors or lead to connection failure.

6.3. Use Quality Tools

Utilize high-quality tools designed for HDC connector installation to ensure precision and prevent damage during the process.

7. Troubleshooting Common Issues

Even with proper selection and installation, issues may arise with HDC connectors. Here are some common problems and how to troubleshoot them:

7.1. Poor Connection Quality

If you experience intermittent connections, check for contamination or damage to the connector pins. Cleaning or replacing the connector may be necessary.

7.2. Overheating

Overheating can be a sign of excessive current flow. Verify that the connector's rating matches the application's requirements, and check for short circuits.

7.3. Physical Damage

Regularly inspect connectors for physical damage, such as cracks or broken locking mechanisms. Damaged connectors should be replaced immediately to prevent further issues.

8. Conclusion

Selecting the right HDC connector is a critical decision that can significantly impact the performance and reliability of your electrical projects. By understanding the different types, specifications, and best practices for installation, you can make informed choices that meet your project's needs. Investing time in the selection process will pay off in the long run, ensuring that your connections stand the test of time and environmental challenges.

9. Frequently Asked Questions

9.1. What factors should I consider when choosing an HDC connector?

Consider factors such as contact rating, temperature range, and the type of locking mechanism when selecting an HDC connector.

9.2. How do I know if my HDC connector is suitable for my application?

Review the specifications provided by the manufacturer and ensure they align with your application’s requirements.

9.3. Can HDC connectors be used in outdoor applications?

Yes, many HDC connectors are designed with environmental resistance, making them suitable for outdoor use. Always check the specifications for environmental ratings.

9.4. What is the typical lifespan of an HDC connector?

The lifespan varies based on application and environmental conditions, but high-quality HDC connectors can last for many years with proper usage and maintenance.

9.5. How can I troubleshoot connection issues with my HDC connectors?

Inspect for contamination, check torque specifications, and replace damaged connectors to troubleshoot any connection issues effectively.

Related news

Introduction to the China International Industry Fair The China International Industry Fair (abbreviated as “China Industry Fair” or “Industry Fair”) is one of China's longest-running national-level industrial exhibitions bearing the “China” designation. Since its inception in 1999,

READ MORE

OUKERUI | New Products New inserts for rectangular connectors

On the basis of the original inserts, we have newly developed straight inserts and cold pressed pins to make the installation of heavy-duty connectors more convenient and more options

READ MORE

The three-day 2025 exhibition Shanghai Electronics Show (electronica China 2025) came to an end yesterday at the Shanghai New International Expo Center. As a benchmark enterprise in the field of heavy-duty connectors, Ningbo OUKERUI Connector Co., Ltd. made a stunning debut in exhibition with multiple innovative products and solutions

READ MORE