SUPPORT

Download

More details of products parameters, more comprehensive technical guidance, please refer to our PDF, or contact us directly.

F·A·Q

What are the application scenarios of Cable Gland?

Cable Gland, also known as Cable Connector or Cable Fitting, is an electrical component used for cable protection and fixation. Cable Gland usually acts as a connector between cables and jacks, and provides protection and retention to protect cables and connectors.

The following are some application scenarios of Cable Gland:

Industrial occasions. Cable Gland is usually used in factories and equipment to fix, protect and prevent cables from falling off to ensure the safety and reliability of equipment operation. They can be used in a variety of environments, including damp, dusty and chemically aggressive environments.

Oil and gas industry. Because Cable Glands are explosion-proof and fire-proof, they are often used in hazardous areas in the oil and gas industry, such as oil wells, refineries and chemical plants.

Aerospace. Cable Gland is widely used in the aerospace field to fix and protect cables to ensure reliable and safe operation of aircraft and satellites.

Medical equipment. Cable Gland is widely used in medical equipment to ensure equipment performance and safety. For example, they are used in hospital beds and surgical lights to protect cables and connectors and prevent misoperation.

In short, Cable Gland can protect cables and connectors in various environments, making the operation of electrical equipment safer and more reliable.

What are Heavy Duty Connector Hoods?

Heavy Duty Connector Hoods are ruggedized devices designed to protect electrical connectors and junction boxes. These shields are typically made from wear-resistant, corrosion-resistant materials such as stainless steel or special plastic alloys to handle harsh industrial environments.

The primary function of Heavy Duty Connector Hoods is to provide additional protection for electrical connections, preventing dust, moisture, chemicals and other potential contaminants from entering the interior of the connector and affecting its performance and reliability. In factories, warehouses, construction sites and other environments, these protective covers are critical to ensuring the normal operation of electrical systems.

Heavy Duty Connector Hoods also have high mechanical strength and can resist external shock and vibration, protecting the connector from damage.

Therefore, Heavy Duty Connector Hoods have become one of the indispensable devices in many industrial fields.

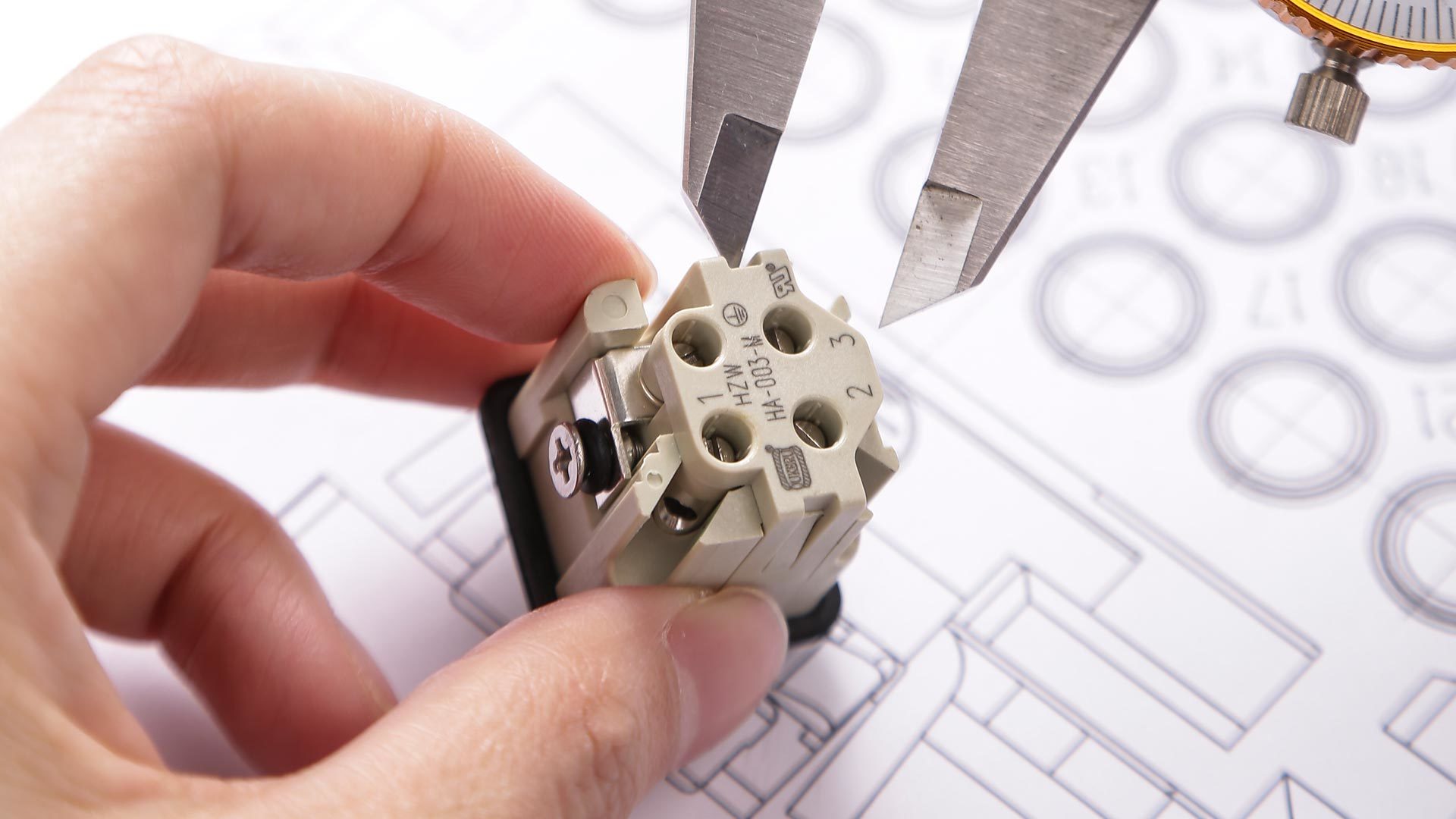

What is Heavy Duty Connector Insert?

Heavy Duty Connector Insert, is an electrical connector assembly specifically designed to withstand high load, high vibration and high shock environments. It is commonly used in fields such as industry, military, aerospace and heavy machinery that require high reliability and durability.

Heavy Duty Connector Insert is made from high-strength materials to ensure a stable electrical connection under a variety of extreme conditions. Its design takes into account contact resistance, insulation performance, mechanical strength and other aspects to ensure the safety and reliability of the connection.

In addition, Heavy Duty Connector Insert usually has good waterproof, dustproof and anti-corrosion properties to adapt to various harsh environments. They also feature easy installation, removal and maintenance, allowing users to quickly replace or repair when needed.

To sum up, Heavy Duty Connector Insert is a high-performance, high-reliability electrical connector assembly that provides stable electrical connections for a variety of heavy-duty equipment and systems.