Why Choose Rectangular Connector Housing for Your Wiring Needs?

Why Choose Rectangular Connector Housing for Your Wiring Needs? Table of Contents 1. Introduction to Rectangular Connector Housing 2. What Are Rectangular Connectors? 3. Benefits of Rectangular Connector Housing 3.1 Durability and Reliability 3.2 Design Flexibility 3.3 Space Efficiency 3.4 Cost-Effectiveness 4. Applications of Rect

Why Choose Rectangular Connector Housing for Your Wiring Needs?

Table of Contents

- 1. Introduction to Rectangular Connector Housing

- 2. What Are Rectangular Connectors?

- 3. Benefits of Rectangular Connector Housing

- 4. Applications of Rectangular Connectors

- 5. How to Choose the Right Rectangular Connector Housing

- 6. Installation Tips for Rectangular Connectors

- 7. Maintenance and Care for Your Connectors

- 8. Frequently Asked Questions (FAQs)

- 9. Conclusion

1. Introduction to Rectangular Connector Housing

In the realm of electrical wiring, selecting the appropriate connector housing is crucial for ensuring optimal performance and reliability. **Rectangular connector housings** have emerged as a preferred choice for various applications due to their distinct design and functionality. This article aims to provide a detailed exploration of why rectangular connector housing is a superior option for your wiring needs.

2. What Are Rectangular Connectors?

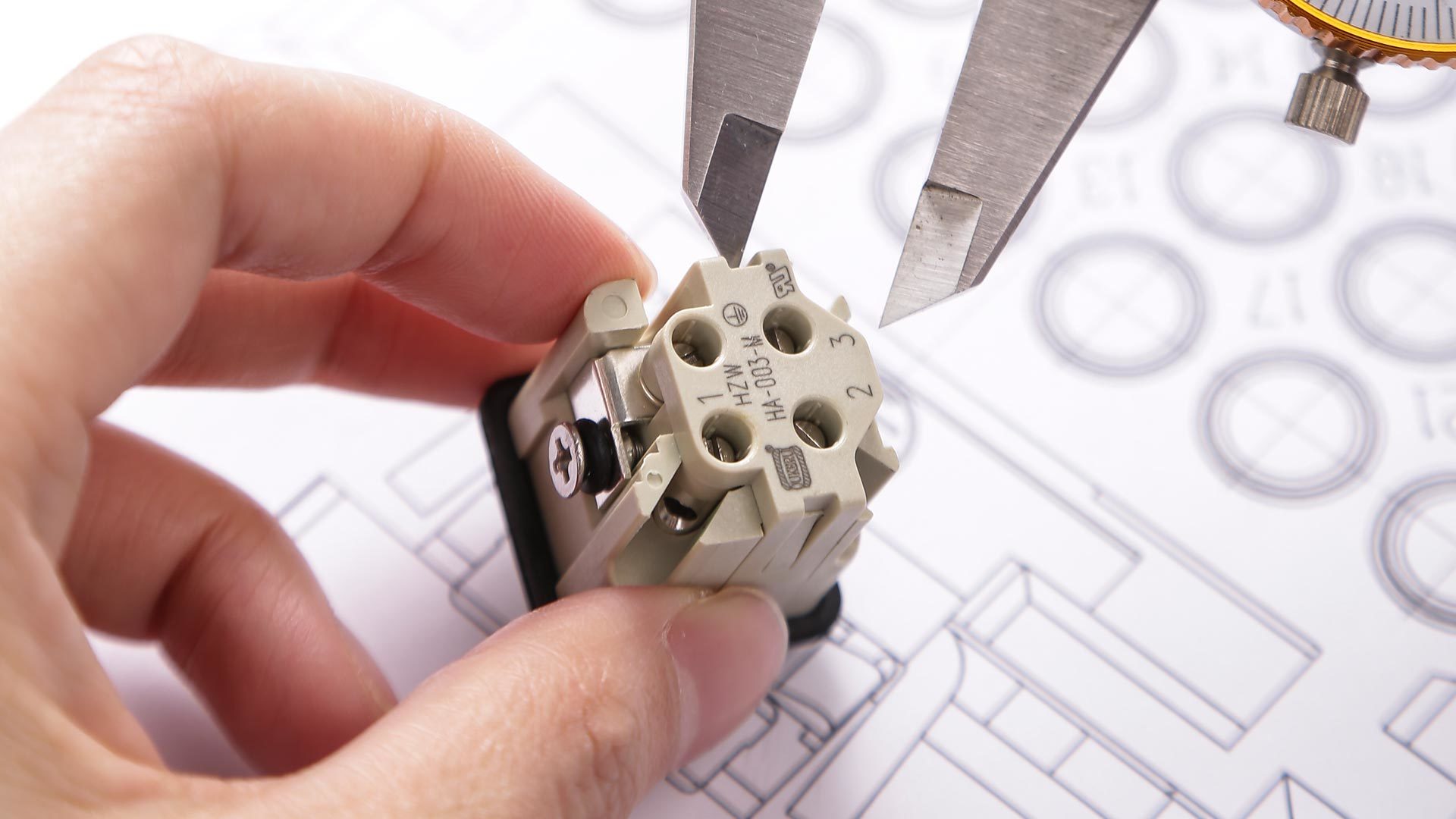

Rectangular connectors are multi-pin connection devices characterized by their rectangular shape. They serve crucial roles in transmitting electrical signals and power between different components in electronic and electrical systems. **These connectors typically consist of two main parts: the housing and the contacts**, which work together to establish a secure and reliable electrical connection.

The housing is designed to protect the internal contacts from environmental elements such as dust, moisture, and mechanical stress, ensuring long-lasting performance. This structure makes rectangular connectors particularly suitable for industrial, automotive, and telecommunications applications.

3. Benefits of Rectangular Connector Housing

Rectangular connector housings offer numerous advantages that make them an ideal choice for a variety of wiring needs. Here, we delve into the key benefits that set them apart from other connector types.

3.1 Durability and Reliability

One of the standout features of rectangular connector housings is their exceptional **durability**. Made from high-quality materials such as thermoplastic or metal, these housings are engineered to withstand harsh environmental conditions, including extreme temperatures, moisture, and vibration. This resilience translates to a longer lifespan for your electrical connections, reducing the need for frequent replacements.

Moreover, the robust design minimizes the risk of accidental disconnection during operation, **ensuring consistent performance** even in demanding applications.

3.2 Design Flexibility

Rectangular connector housings are available in various configurations, allowing for significant design flexibility. Whether you require a connector with multiple pins or a specific arrangement to fit a unique layout, there’s likely a rectangular connector that meets your specifications. This versatility makes them suitable for a wide range of applications, from consumer electronics to heavy machinery.

Additionally, many rectangular connectors come with the option for customization, enabling engineers to tailor connectors to specific project requirements. This adaptability is invaluable in fast-paced industries where innovation and efficiency are paramount.

3.3 Space Efficiency

In many applications, space is a premium commodity. **Rectangular connectors** are designed with a compact footprint, allowing for efficient use of available space. Their organized pin layout ensures that multiple connectors can be installed close together without compromising accessibility or performance.

This space efficiency is particularly beneficial in applications such as telecommunications equipment, where maximizing real estate can enhance overall system performance and integration.

3.4 Cost-Effectiveness

While the initial investment for rectangular connector housings may vary, their **long-term cost-effectiveness** cannot be overlooked. The durability and reliability of these connectors often lead to reduced maintenance costs and fewer replacements over time. Furthermore, the ease of installation and potential for customization can save labor costs during assembly and integration.

In the grand scheme, investing in quality rectangular connector housings can yield significant savings, making them a smart choice for both small-scale projects and large industrial applications.

4. Applications of Rectangular Connectors

Rectangular connectors are widely used across various industries due to their versatility. Below are some key applications where these connectors excel:

4.1 Industrial Automation

In industrial automation, rectangular connectors facilitate effective communication between control systems, sensors, and actuators. Their robustness and ability to withstand harsh conditions make them ideal for factory settings.

4.2 Automotive Industry

The automotive sector relies heavily on rectangular connectors for wiring harnesses that connect critical components such as lighting systems, sensors, and power distribution units. Their durability ensures reliable performance in vehicles.

4.3 Telecommunications

In telecommunications equipment, rectangular connectors enable efficient signal transmission between devices. Their compact design helps optimize space in densely packed environments like server rooms.

4.4 Aerospace and Defense

Given the high stakes in aerospace and defense applications, the reliability of rectangular connectors is paramount. These connectors are designed to meet rigorous standards, ensuring safety and effectiveness in critical systems.

5. How to Choose the Right Rectangular Connector Housing

Selecting the right rectangular connector housing is crucial for ensuring compatibility and performance. Here are some factors to consider:

5.1 Determine the Number of Pins Required

Assess your connection needs to determine how many pins are necessary for your application. Rectangular connectors are available in various pin configurations.

5.2 Consider Environmental Conditions

Evaluate the environmental factors your connectors will face. If your application involves exposure to moisture, dust, or extreme temperatures, prioritize connectors designed for these conditions.

5.3 Evaluate Size and Space Constraints

Take into account the physical dimensions of the connector and the available installation space. Select a connector that fits within your design constraints while still providing adequate performance.

5.4 Review Connector Specifications

Carefully review the specifications of potential connectors, including current and voltage ratings, to ensure they meet the operational requirements of your system.

5.5 Seek Customization Options

If your project has unique needs, explore customization options offered by manufacturers. Tailored solutions can enhance performance and streamline integration.

6. Installation Tips for Rectangular Connectors

Proper installation of rectangular connectors is vital for achieving optimal performance. Here are some tips to consider:

6.1 Follow Manufacturer Guidelines

Always adhere to the manufacturer’s installation instructions to ensure proper alignment and secure connections.

6.2 Use Appropriate Tools

Utilize the right tools for installation to avoid damaging the connector or housing. A proper crimping tool can enhance connection integrity.

6.3 Inspect Connectors Before Use

Before installation, inspect connectors for any signs of damage or defects. Ensuring that connectors are in good condition will prevent issues later on.

6.4 Test Connections Post-Installation

After installation, conduct tests to verify that connections are secure and functioning as intended. This step is essential for identifying any potential problems early on.

7. Maintenance and Care for Your Connectors

Maintaining your rectangular connectors can prolong their lifespan and enhance performance. Here are some essential maintenance practices:

7.1 Regular Inspections

Conduct routine inspections to identify wear and tear. Look for corrosion, loose connections, or any physical damage that could compromise functionality.

7.2 Keep Connectors Clean

Ensure that connectors remain free from dust, dirt, and moisture. Use appropriate cleaning methods to avoid damaging the housing or contacts.

7.3 Avoid Overloading

Ensure that the current and voltage supplied to the connectors do not exceed their specified ratings. Overloading can lead to overheating and eventual failure.

7.4 Store Properly

If connectors are not in use, store them in a dry, cool environment to prevent environmental damage. Proper storage practices can help maintain their integrity.

8. Frequently Asked Questions (FAQs)

8.1 What materials are rectangular connectors made from?

Rectangular connectors are typically made from durable materials such as thermoplastics, metals, and sometimes elastomers for sealing.

8.2 Are rectangular connectors waterproof?

Many rectangular connectors are designed to be waterproof or water-resistant, making them suitable for various outdoor and industrial applications. Always check the specifications for environmental ratings.

8.3 How do I know if I need a rectangular connector for my project?

If your project involves multiple connections with a need for durability, compact design, and reliability, a rectangular connector is likely a suitable choice.

8.4 Can rectangular connectors be reused?

Yes, rectangular connectors can often be reused if they are still in good condition. However, it’s essential to inspect them for any signs of wear or damage before reinstallation.

8.5 Where can I purchase rectangular connectors?

Rectangular connectors can be purchased from electronic component suppliers, distributors, and online marketplaces specializing in electrical components.

9. Conclusion

In the world of electrical wiring, the choice of connector housing is critical to ensuring reliable performance and longevity. **Rectangular connector housings** stand out as an excellent option, offering versatility, durability, and cost-effectiveness. With a range of applications across multiple industries, these connectors meet the needs of modern technology while providing the flexibility required for innovative designs. By understanding the benefits and best practices associated with rectangular connectors, you can make informed decisions that enhance the integrity and efficiency of your electrical systems. Choosing the right connector for your wiring needs is not just an option; it is a necessity for success in today's fast-paced technological landscape.

Related news

Introduction to the China International Industry Fair The China International Industry Fair (abbreviated as “China Industry Fair” or “Industry Fair”) is one of China's longest-running national-level industrial exhibitions bearing the “China” designation. Since its inception in 1999,

READ MORE

OUKERUI | New Products New inserts for rectangular connectors

On the basis of the original inserts, we have newly developed straight inserts and cold pressed pins to make the installation of heavy-duty connectors more convenient and more options

READ MORE

The three-day 2025 exhibition Shanghai Electronics Show (electronica China 2025) came to an end yesterday at the Shanghai New International Expo Center. As a benchmark enterprise in the field of heavy-duty connectors, Ningbo OUKERUI Connector Co., Ltd. made a stunning debut in exhibition with multiple innovative products and solutions

READ MORE