Heavy Duty Spade Connectors: The Key to Secure Electrical Connections

Heavy Duty Spade Connectors: The Key to Secure Electrical Connections Table of Contents Understanding Heavy Duty Spade Connectors Benefits of Using Heavy Duty Spade Connectors Applications of Heavy Duty Spade Connectors How to Install Heavy Duty Spade Connectors Choosing the Right Heavy Duty Spade Connector Maintenance and Care of Heavy Duty Spade Connectors Common Iss

Heavy Duty Spade Connectors: The Key to Secure Electrical Connections

Table of Contents

- Understanding Heavy Duty Spade Connectors

- Benefits of Using Heavy Duty Spade Connectors

- Applications of Heavy Duty Spade Connectors

- How to Install Heavy Duty Spade Connectors

- Choosing the Right Heavy Duty Spade Connector

- Maintenance and Care of Heavy Duty Spade Connectors

- Common Issues and Solutions

- Frequently Asked Questions

- Conclusion

Understanding Heavy Duty Spade Connectors

Heavy-duty spade connectors are widely used in various electrical applications due to their durability and reliability. These connectors consist of a flat, spade-like terminal that allows for easy and secure connection to electrical components. They are designed to handle higher currents and provide a reliable electrical connection in environments where vibration, moisture, and temperature changes may occur.

The design of a heavy-duty spade connector typically includes a thick metal blade that can be inserted into a corresponding connector. This connection ensures minimal resistance, enabling efficient power transfer. Heavy-duty spade connectors come in various sizes and configurations, making them versatile for many applications.

Benefits of Using Heavy Duty Spade Connectors

The advantages of using heavy-duty spade connectors extend beyond just electrical efficiency. Here are some key benefits:

1. Enhanced Durability

Heavy-duty spade connectors are made from robust materials, such as copper or brass, which resist corrosion and wear over time. Their design ensures they can withstand harsh conditions, making them ideal for automotive, industrial, and marine applications.

2. Easy to Use

The installation of heavy-duty spade connectors is straightforward. Their design allows for tool-free installation in many cases, making them user-friendly for both professionals and DIY enthusiasts. The connectors can be easily attached and detached as needed without damaging the wire or terminal.

3. Reliable Electrical Connection

These connectors provide a solid electrical connection, reducing the chances of failure due to loose connections. This reliability is crucial in applications where consistent performance is necessary to ensure safety and efficiency.

4. Versatile Applications

Heavy-duty spade connectors are suitable for various applications, from automotive wiring to home appliances. Their versatility makes them a preferred choice for many electrical projects.

Applications of Heavy Duty Spade Connectors

Heavy-duty spade connectors find usage in multiple sectors due to their versatility and reliability. Some common applications include:

1. Automotive Wiring

In automotive applications, heavy-duty spade connectors are used to connect battery terminals, lights, and other electrical components. Their ability to withstand vibrations and temperature fluctuations makes them ideal for vehicles.

2. Industrial Machinery

Heavy-duty spade connectors are frequently used in industrial machines, where robust wiring connections are necessary to ensure safe and efficient operation. They are often found in manufacturing equipment, conveyor systems, and heavy-duty power tools.

3. Marine Environments

Due to their corrosion-resistant properties, heavy-duty spade connectors are commonly used in marine applications. They provide reliable connections for electrical systems in boats and other watercraft, ensuring safety in challenging conditions.

4. Home Appliances

Heavy-duty spade connectors are also utilized in various home appliances, such as refrigerators, washing machines, and HVAC systems. Their reliability contributes to the efficient operation of these devices.

How to Install Heavy Duty Spade Connectors

Installing heavy-duty spade connectors is a straightforward process if done correctly. Follow these steps for a successful installation:

Step 1: Gather Your Tools

You will need the following tools:

- Wire stripper

- Crimping tool

- Heavy-duty spade connectors

- Insulation tape (optional)

Step 2: Prepare the Wires

Strip about half an inch of insulation from the end of the wire using a wire stripper. Ensure that you do not damage the wire strands.

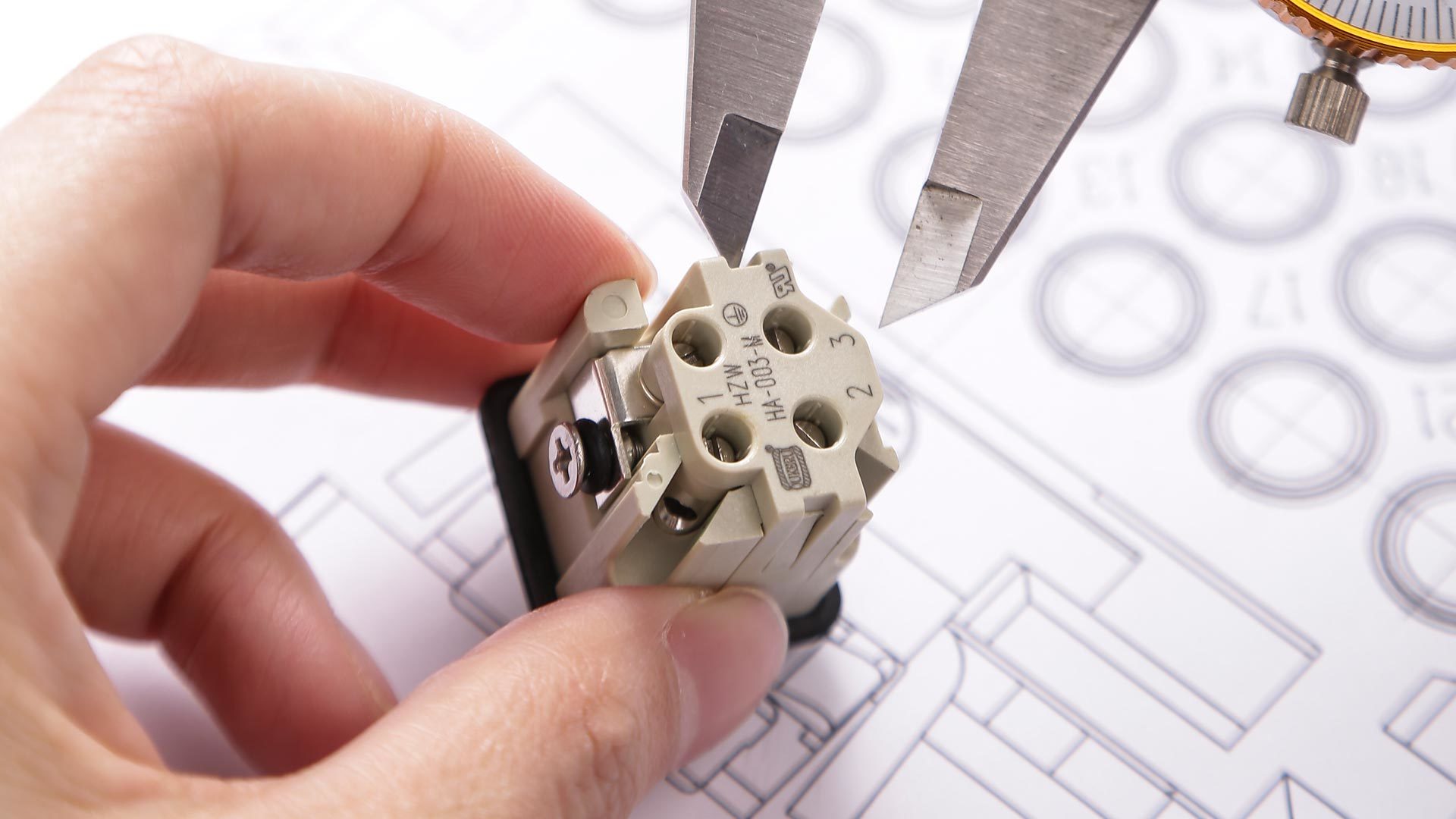

Step 3: Crimp the Connector

Insert the stripped wire into the barrel of the heavy-duty spade connector. Using a crimping tool, firmly crimp the connector onto the wire to ensure a secure fit. Make sure there are no exposed wire strands that could cause a short circuit.

Step 4: Test the Connection

Before finalizing the installation, it’s important to test the connection. Gently pull on the wire to ensure it is securely attached. If it comes loose, re-crimp the connector.

Step 5: Insulate (Optional)

If desired, wrap insulation tape around the connection to provide additional protection against moisture and environmental factors.

Choosing the Right Heavy Duty Spade Connector

Selecting the appropriate heavy-duty spade connector is crucial for ensuring reliable electrical connections. Here are some factors to consider:

1. Size and Gauge of Wire

Choose a connector that is compatible with the wire gauge you are using. Ensure that the connector can handle the current required for your application.

2. Material

Opt for connectors made from high-quality materials like copper or brass for better conductivity and durability. Check for any corrosion-resistant coatings that may enhance the longevity of the connector.

3. Insulation Type

Some heavy-duty spade connectors come with insulation. Depending on your application, you may want to choose connectors with or without insulation to suit your needs.

4. Environmental Factors

Consider the environment in which the spade connectors will be used. If exposed to moisture or extreme temperatures, select connectors designed to withstand these conditions.

Maintenance and Care of Heavy Duty Spade Connectors

Proper maintenance can extend the life of heavy-duty spade connectors and ensure they function effectively. Here are some care tips:

1. Regular Inspections

Conduct regular inspections of the connectors to check for signs of corrosion, wear, or looseness. Address any issues promptly to prevent further damage.

2. Clean Connections

Keep the connections clean and free from dirt or moisture. Use a dry cloth to wipe down connectors periodically.

3. Correct Torque Specifications

When installing connectors, ensure that you use the correct torque specifications to avoid over-tightening, which can damage the connector or the wire.

Common Issues and Solutions

While heavy-duty spade connectors are generally reliable, some issues may arise. Here are common problems and their solutions:

1. Loose Connections

Problem: Loose connections can lead to intermittent electrical issues or complete failures.

Solution: Re-crimp the connector or replace it if necessary to ensure a tight fit.

2. Corrosion

Problem: Corrosion can occur over time, especially in humid environments, leading to poor connectivity.

Solution: Clean the connectors and consider using anti-corrosion sprays or coatings.

3. Overheating

Problem: Overheating can indicate that the connector is not rated for the current it is handling.

Solution: Check the wire gauge and connector rating. Upgrade to a higher-rated connector if necessary.

Frequently Asked Questions

1. What is the difference between heavy-duty and standard spade connectors?

Heavy-duty spade connectors are designed to handle higher currents and have thicker blades for improved durability compared to standard spade connectors.

2. Can I use heavy-duty spade connectors in outdoor applications?

Yes, provided they are made from corrosion-resistant materials. Always check the specifications to ensure they can withstand outdoor conditions.

3. How do I know which size spade connector to use?

Choose a connector that matches the wire gauge you are using. Refer to the manufacturer's specifications for guidance.

4. Are heavy-duty spade connectors reusable?

Yes, heavy-duty spade connectors can be reused, but ensure they are in good condition and securely crimped each time they are reinstalled.

5. What tools do I need to install heavy-duty spade connectors?

You will need a wire stripper, crimping tool, and, optionally, insulation tape for added protection.

Conclusion

Heavy-duty spade connectors are essential components for secure electrical connections across various applications. Their durability, ease of use, and reliability make them a top choice for professionals and DIY enthusiasts alike. By understanding their benefits, applications, and proper installation methods, you can ensure that your electrical projects are safe and efficient. With regular maintenance and the right selection criteria, heavy-duty spade connectors will provide long-lasting performance and peace of mind in your electrical systems.

Related news

Introduction to the China International Industry Fair The China International Industry Fair (abbreviated as “China Industry Fair” or “Industry Fair”) is one of China's longest-running national-level industrial exhibitions bearing the “China” designation. Since its inception in 1999,

READ MORE

OUKERUI | New Products New inserts for rectangular connectors

On the basis of the original inserts, we have newly developed straight inserts and cold pressed pins to make the installation of heavy-duty connectors more convenient and more options

READ MORE

The three-day 2025 exhibition Shanghai Electronics Show (electronica China 2025) came to an end yesterday at the Shanghai New International Expo Center. As a benchmark enterprise in the field of heavy-duty connectors, Ningbo OUKERUI Connector Co., Ltd. made a stunning debut in exhibition with multiple innovative products and solutions

READ MORE