Exploring the Benefits of High-Quality Busbar Connectors for Electrical Systems

Exploring the Benefits of High-Quality Busbar Connectors for Electrical Systems Table of Contents 1. Introduction to Busbar Connectors 2. Importance of High-Quality Connectors in Electrical Applications 3. Key Benefits of Using Busbar Connectors 3.1 Enhanced Electrical Performance 3.2 Improved Reliability and Longevity 3.3 Cost-Effectiveness in the Long Run 3.4 Safety Features of H

Exploring the Benefits of High-Quality Busbar Connectors for Electrical Systems

Table of Contents

1. Introduction to Busbar Connectors

2. Importance of High-Quality Connectors in Electrical Applications

3. Key Benefits of Using Busbar Connectors

3.1 Enhanced Electrical Performance

3.2 Improved Reliability and Longevity

3.3 Cost-Effectiveness in the Long Run

3.4 Safety Features of High-Quality Busbar Connectors

4. Types of Busbar Connectors

4.1 Screw-Type Connectors

4.2 Crimp-Type Connectors

4.3 Plug-In Connectors

5. Choosing the Right Busbar Connector for Your Needs

6. Installation Best Practices for Busbar Connectors

7. Frequently Asked Questions (FAQs)

8. Conclusion

1. Introduction to Busbar Connectors

Busbar connectors play a pivotal role in electrical systems by providing a reliable means of connecting various electrical components. Typically made from high-conductivity materials such as copper or aluminum, these connectors facilitate the efficient transfer of electrical currents between various power distribution points. In modern electrical installations, the importance of high-quality busbar connectors cannot be overstated, as they contribute significantly to the overall performance and safety of the system.

2. Importance of High-Quality Connectors in Electrical Applications

In today's fast-paced and technology-driven world, the demand for efficient and reliable electrical systems is more prominent than ever. High-quality busbar connectors are essential for ensuring optimal performance, safety, and longevity of electrical installations. Investing in superior connectors not only minimizes the risk of failures but also enhances the efficiency of energy distribution, leading to cost savings in the long term.

3. Key Benefits of Using Busbar Connectors

When considering the integration of busbar connectors into electrical systems, several benefits stand out:

3.1 Enhanced Electrical Performance

High-quality busbar connectors are designed to minimize resistance and maximize conductivity. This results in reduced energy losses during transmission, ensuring that more of the supplied electrical energy is utilized effectively. Improved conductivity translates to better overall system performance, which is particularly crucial in industrial and commercial applications where large amounts of power are transferred.

3.2 Improved Reliability and Longevity

One of the most significant advantages of high-quality busbar connectors is their reliability. Manufactured from durable materials and designed to withstand extreme conditions, these connectors offer superior performance over time. This reliability reduces the need for frequent replacements and maintenance, providing peace of mind for facility managers and electrical engineers alike.

3.3 Cost-Effectiveness in the Long Run

While the initial investment in high-quality busbar connectors may be higher than that of lower-quality alternatives, the long-term savings can be substantial. Reduced maintenance costs, fewer replacements, and enhanced energy efficiency lead to cost savings that outweigh the initial expenditure. Consequently, choosing high-quality connectors is a financially sound decision for any electrical installation.

3.4 Safety Features of High-Quality Busbar Connectors

Safety is a paramount concern in electrical installations. High-quality busbar connectors are engineered with safety features that minimize the risk of short circuits, overheating, and electrical fires. These connectors often include insulation and protective covers that help prevent accidental contact with live components, ensuring a safer working environment.

4. Types of Busbar Connectors

Understanding the various types of busbar connectors available is essential for selecting the best option for your electrical system:

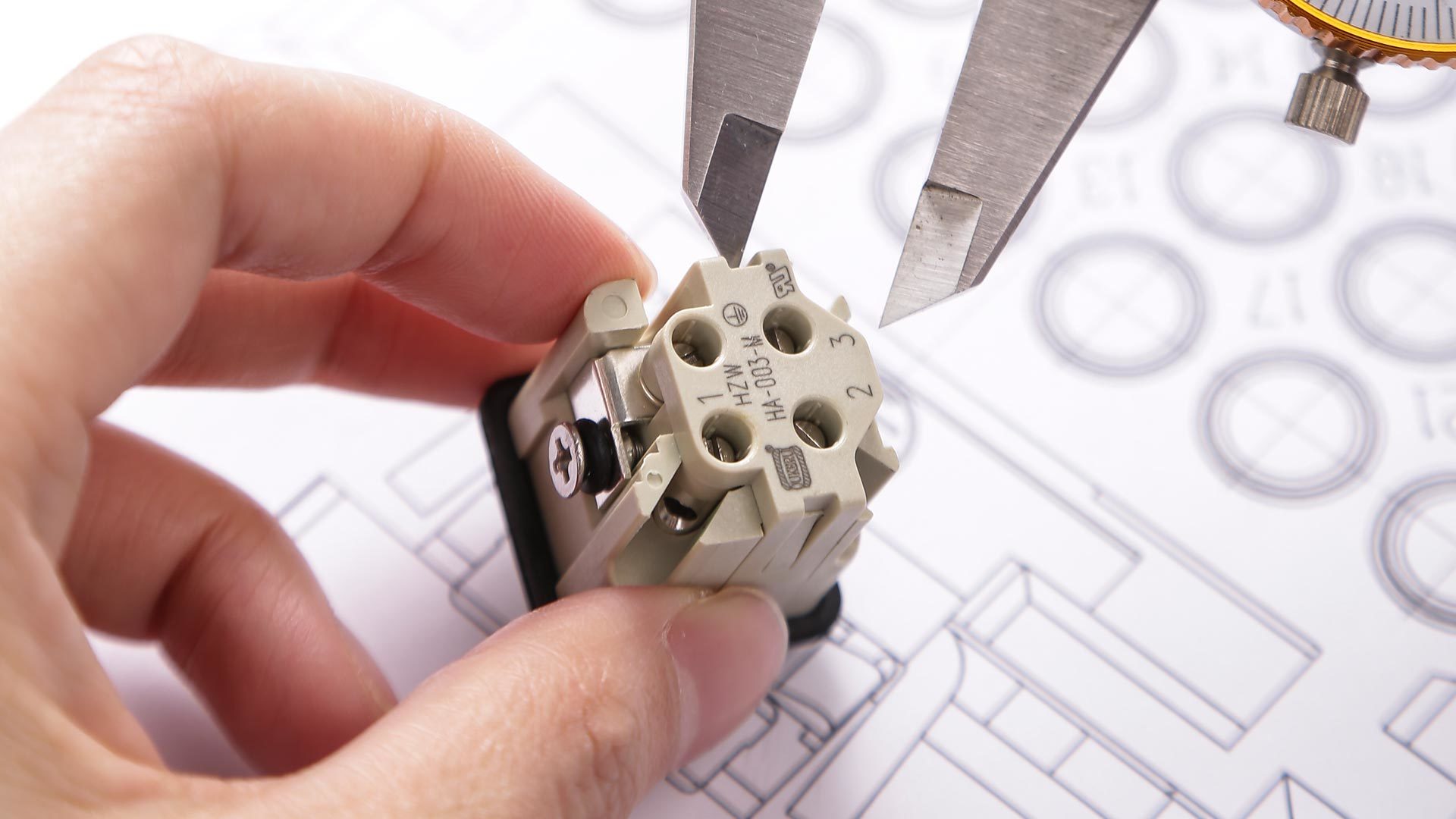

4.1 Screw-Type Connectors

Screw-type connectors are commonly used in applications where a secure and durable connection is required. These connectors utilize screws to fasten the busbars together, ensuring a strong electrical and mechanical connection. They are easy to install and are suitable for high-current applications.

4.2 Crimp-Type Connectors

Crimp-type connectors provide a permanent and reliable connection through the crimping process, which deforms the connector around the busbar. This type of connection is known for its low resistance and high conductivity, making it ideal for applications demanding high performance and reliability.

4.3 Plug-In Connectors

Plug-in connectors allow for quick and easy connections and disconnections, making them ideal for modular electrical systems. These connectors are particularly beneficial in applications where components need to be frequently replaced or upgraded.

5. Choosing the Right Busbar Connector for Your Needs

Selecting the appropriate busbar connector involves several considerations:

- **Current Rating**: Ensure that the connector can handle the expected load without overheating.

- **Material**: Consider the conductivity of the material, with copper being the preferred choice for most applications.

- **Environmental Conditions**: Select connectors that can withstand specific environmental factors such as humidity, temperature, and potential corrosion.

By evaluating these factors, you can determine the most suitable busbar connector for your electrical system.

6. Installation Best Practices for Busbar Connectors

Proper installation is crucial for the performance and longevity of busbar connectors. Here are some best practices to keep in mind:

- **Follow Manufacturer Guidelines**: Always adhere to the installation instructions provided by the manufacturer to ensure optimal performance.

- **Use Appropriate Tools**: Utilize the correct tools for installing connectors, including torque wrenches for screw-type connectors to ensure proper tightness.

- **Inspect Connections**: Regularly check and maintain connections to prevent loosening and corrosion, which can lead to failures.

Implementing these best practices can significantly enhance the effectiveness of your busbar connectors.

7. Frequently Asked Questions (FAQs)

**Q1: What is the primary function of busbar connectors?**

A1: Busbar connectors serve to connect various electrical components, facilitating the efficient distribution of electrical power.

**Q2: How do I determine the appropriate size of a busbar connector?**

A2: The appropriate size can be determined by evaluating the current rating and the physical dimensions of your electrical installation.

**Q3: Are high-quality busbar connectors worth the investment?**

A3: Yes, high-quality connectors offer enhanced performance, reliability, and cost-effectiveness in the long run, making them a wise investment.

**Q4: Can I install busbar connectors myself, or should I hire a professional?**

A4: While DIY installation is possible, hiring a professional is recommended for complex systems to ensure safety and compliance with regulations.

**Q5: What maintenance do busbar connectors require?**

A5: Regular inspections for wear and corrosion, along with tightening of connections, are crucial for maintaining the integrity and performance of busbar connectors.

8. Conclusion

In conclusion, high-quality busbar connectors are indispensable components in modern electrical systems. Their numerous benefits, including enhanced electrical performance, improved reliability, and long-term cost-effectiveness, make them essential for efficient energy distribution. By understanding the types of connectors available and adhering to proper installation practices, you can ensure that your electrical installations are safe, efficient, and durable. Investing in superior busbar connectors not only enhances the performance of your systems but also contributes to overall safety and reliability in various applications.

Related news

Introduction to the China International Industry Fair The China International Industry Fair (abbreviated as “China Industry Fair” or “Industry Fair”) is one of China's longest-running national-level industrial exhibitions bearing the “China” designation. Since its inception in 1999,

READ MORE

OUKERUI | New Products New inserts for rectangular connectors

On the basis of the original inserts, we have newly developed straight inserts and cold pressed pins to make the installation of heavy-duty connectors more convenient and more options

READ MORE

The three-day 2025 exhibition Shanghai Electronics Show (electronica China 2025) came to an end yesterday at the Shanghai New International Expo Center. As a benchmark enterprise in the field of heavy-duty connectors, Ningbo OUKERUI Connector Co., Ltd. made a stunning debut in exhibition with multiple innovative products and solutions

READ MORE