Understanding the Benefits of HDC Connectors in Electrical Engineering

Understanding the Benefits of HDC Connectors in Electrical Engineering Table of Contents What Are HDC Connectors? Types of HDC Connectors Advantages of HDC Connectors in Electrical Engineering Applications of HDC Connectors Installation and Usage of HDC Connectors Maintenance and Care for HDC Connectors The Future of HDC Connectors in Electrical Engineering FAQs About HDC Conn

Understanding the Benefits of HDC Connectors in Electrical Engineering

Table of Contents

- What Are HDC Connectors?

- Types of HDC Connectors

- Advantages of HDC Connectors in Electrical Engineering

- Applications of HDC Connectors

- Installation and Usage of HDC Connectors

- Maintenance and Care for HDC Connectors

- The Future of HDC Connectors in Electrical Engineering

- FAQs About HDC Connectors

What Are HDC Connectors?

HDC connectors, or Heavy Duty Connectors, are essential components in electrical engineering that facilitate the reliable connection of electrical circuits. These connectors are designed to withstand harsh environments and demanding conditions, making them ideal for industrial applications. HDC connectors ensure a secure electrical connection while providing protection against environmental factors such as dust, moisture, and mechanical stress.

Design and Construction

The design of HDC connectors features a robust casing made from materials like plastic or metal, depending on the application requirements. They often incorporate multiple contact arrangements, allowing for a variety of electrical configurations. The contacts themselves are typically made from high-quality conductive materials to ensure minimal resistance and optimal performance.

Types of HDC Connectors

There are several types of HDC connectors, each serving specific purposes in electrical engineering. Understanding these types can help in selecting the right connector for your project.

1. Plug and Socket Connectors

Plug and socket connectors are among the most common HDC connectors, facilitating easy connectivity and disconnection. They are widely used in applications like machinery and automation systems.

2. Panel-Mounted Connectors

Panel-mounted connectors are fixed to a surface, providing a reliable means of connection for devices that require frequent access. These connectors are essential in control panels and automation setups.

3. Cable Connectors

Cable connectors are designed for connecting cables to various equipment. These connectors ensure a secure connection while maintaining flexibility and ease of installation.

4. Customized Connectors

For specialized applications, customized HDC connectors can be developed. These connectors cater to unique requirements, including size, shape, and electrical configuration.

Advantages of HDC Connectors in Electrical Engineering

HDC connectors offer several advantages that make them a preferred choice in various electrical engineering applications.

1. High Durability

One of the primary benefits of HDC connectors is their high durability. They are built to withstand extreme conditions, including temperature fluctuations, humidity, and mechanical stress. This durability ensures longevity and reduces maintenance costs.

2. Enhanced Safety

HDC connectors are designed with safety in mind. They feature locking mechanisms that prevent accidental disconnection, ensuring the safety of personnel and equipment. Additionally, many HDC connectors are compliant with international safety standards.

3. Versatility

These connectors are highly versatile, making them suitable for a wide range of applications, from industrial machinery to telecommunications. Their adaptability allows engineers to use them in diverse environments.

4. Cost-Effectiveness

The initial investment in HDC connectors may be higher than other connector types; however, their durability and low maintenance costs make them a cost-effective choice in the long run.

Applications of HDC Connectors

HDC connectors find applications across various industries, demonstrating their versatility and reliability.

1. Industrial Automation

In industrial settings, HDC connectors are vital for connecting machinery and control systems. They facilitate seamless communication and power transfer, enhancing operational efficiency.

2. Transportation and Automotive

The transportation sector extensively uses HDC connectors in vehicles and public transport systems. Their robustness ensures reliable performance even in challenging environments.

3. Telecommunications

HDC connectors are used in telecommunications equipment to ensure stable and reliable connections, crucial for maintaining communication lines.

4. Renewable Energy Systems

With the rise of renewable energy, HDC connectors are increasingly used in solar and wind energy systems. They facilitate efficient connections between various system components, maximizing energy output.

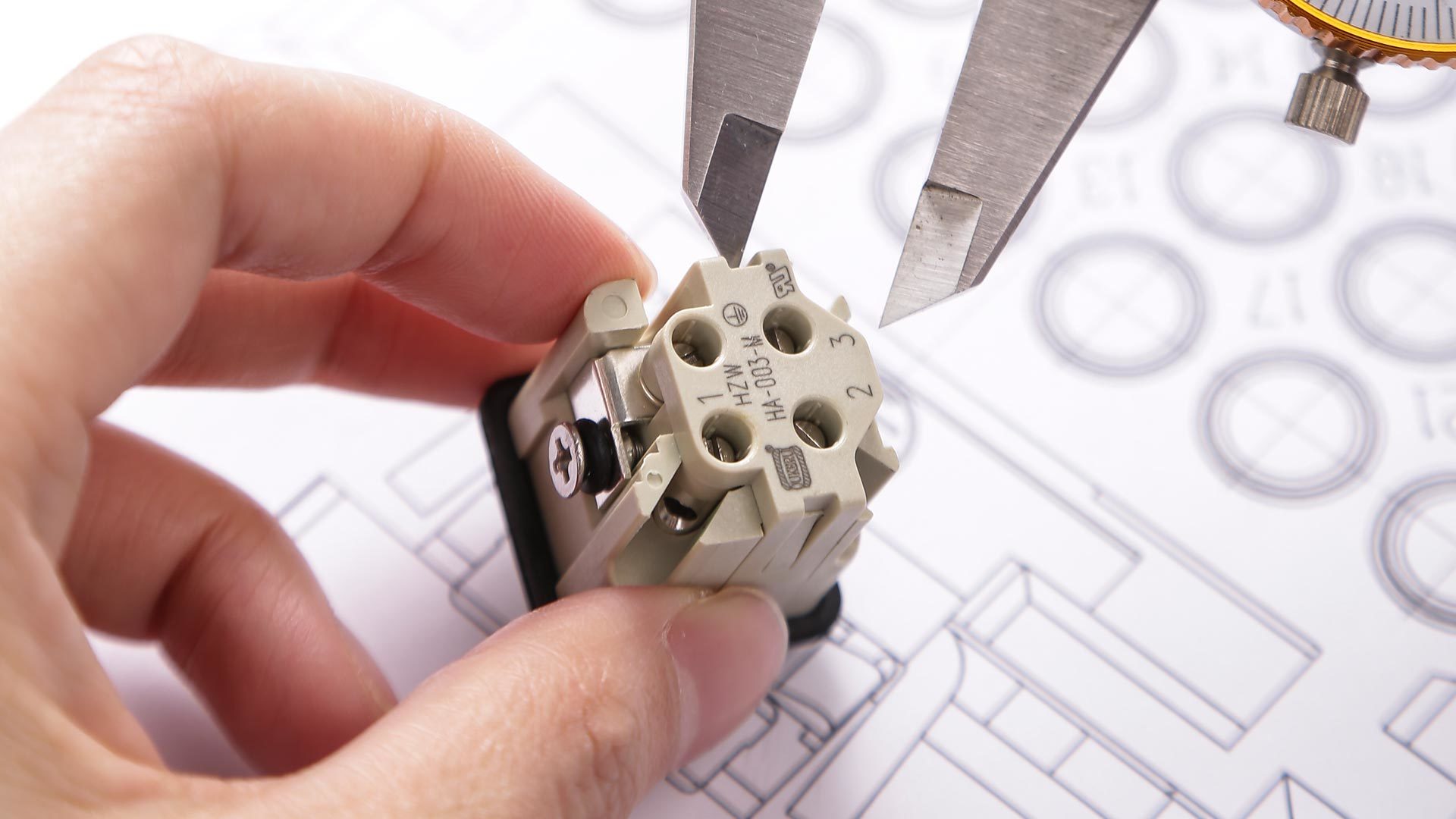

Installation and Usage of HDC Connectors

Proper installation is crucial for the performance of HDC connectors. Following the manufacturer's guidelines ensures reliable and safe connections.

1. Preparation

Before installation, ensure that both the connector and the cables are clean and free of contaminants. Additionally, verify that all components are compatible and suited for the intended application.

2. Tools Required

Using the right tools is essential for a successful installation. Common tools include wire strippers, crimping tools, and screwdrivers. Always refer to the installation manual for specific requirements.

3. Step-by-Step Installation

The installation process typically involves:

- Stripping the wire insulation to expose the conductor.

- Inserting the wire into the connector's contact point.

- Using a crimping tool to secure the connection.

- Testing the connection for continuity and performance.

Maintenance and Care for HDC Connectors

To ensure long-lasting performance, regular maintenance of HDC connectors is essential.

1. Routine Inspections

Conduct routine inspections to identify signs of wear, damage, or corrosion. Early detection can prevent failures and costly downtime.

2. Cleaning Procedures

Regularly clean the connectors to remove dirt and contaminants. Use appropriate cleaning agents and methods as specified by the manufacturer.

3. Environmental Considerations

Ensure that connectors are not exposed to extreme conditions beyond their specified limits. Proper environmental control can significantly extend their lifespan.

The Future of HDC Connectors in Electrical Engineering

The future of HDC connectors looks promising as advancements in technology continue to shape the electrical engineering landscape. Innovations may lead to even more robust designs, enhanced connectivity options, and improved integration with smart technologies. As industries evolve, HDC connectors will play a vital role in facilitating efficient and reliable electrical connections.

FAQs About HDC Connectors

1. What makes HDC connectors different from standard connectors?

HDC connectors are specifically designed for heavy-duty applications, offering enhanced durability, safety, and versatility compared to standard connectors.

2. Can HDC connectors be used in outdoor environments?

Yes, many HDC connectors are rated for outdoor use, featuring protective casings that shield them from environmental elements.

3. How do I choose the right type of HDC connector for my project?

Consider factors such as the application environment, current and voltage requirements, and the type of equipment being connected when selecting an HDC connector.

4. Are HDC connectors easy to install?

Yes, HDC connectors are designed for straightforward installation, provided you follow the manufacturer's guidelines and use the correct tools.

5. What maintenance is required for HDC connectors?

Regular inspections, cleaning, and ensuring proper environmental conditions are essential for maintaining the performance of HDC connectors.

Conclusion

In summary, HDC connectors are a fundamental component in electrical engineering, offering numerous benefits, including durability, safety, versatility, and cost-effectiveness. Their wide range of applications across various industries underscores their importance in modern electrical systems. By understanding the advantages and best practices for installation and maintenance, engineers can harness the full potential of HDC connectors to enhance performance and reliability in their projects.

Related news

OUKERUI | New Products New inserts for rectangular connectors