The Role of Rectangular Connector Housing in Modern Electronics

The Role of Rectangular Connector Housing in Modern Electronics Introduction to Rectangular Connectors In the world of electronics, connectivity stands as a foundational pillar for device functionality. Among various types of connectors, **rectangular connectors** play a crucial role in ensuring reliable electrical connections between components and systems. These connectors are widely used across

The Role of Rectangular Connector Housing in Modern Electronics

Introduction to Rectangular Connectors

In the world of electronics, connectivity stands as a foundational pillar for device functionality. Among various types of connectors, **rectangular connectors** play a crucial role in ensuring reliable electrical connections between components and systems. These connectors are widely used across various industries, providing versatility and reliability. **Rectangular connector housings**, specifically, are integral to the structural integrity and performance of these connectors.

As we explore the role of rectangular connector housing, we will highlight its significance, types, applications, and the innovations driving its evolution in modern electronics.

Understanding Rectangular Connector Housing

What is a Rectangular Connector Housing?

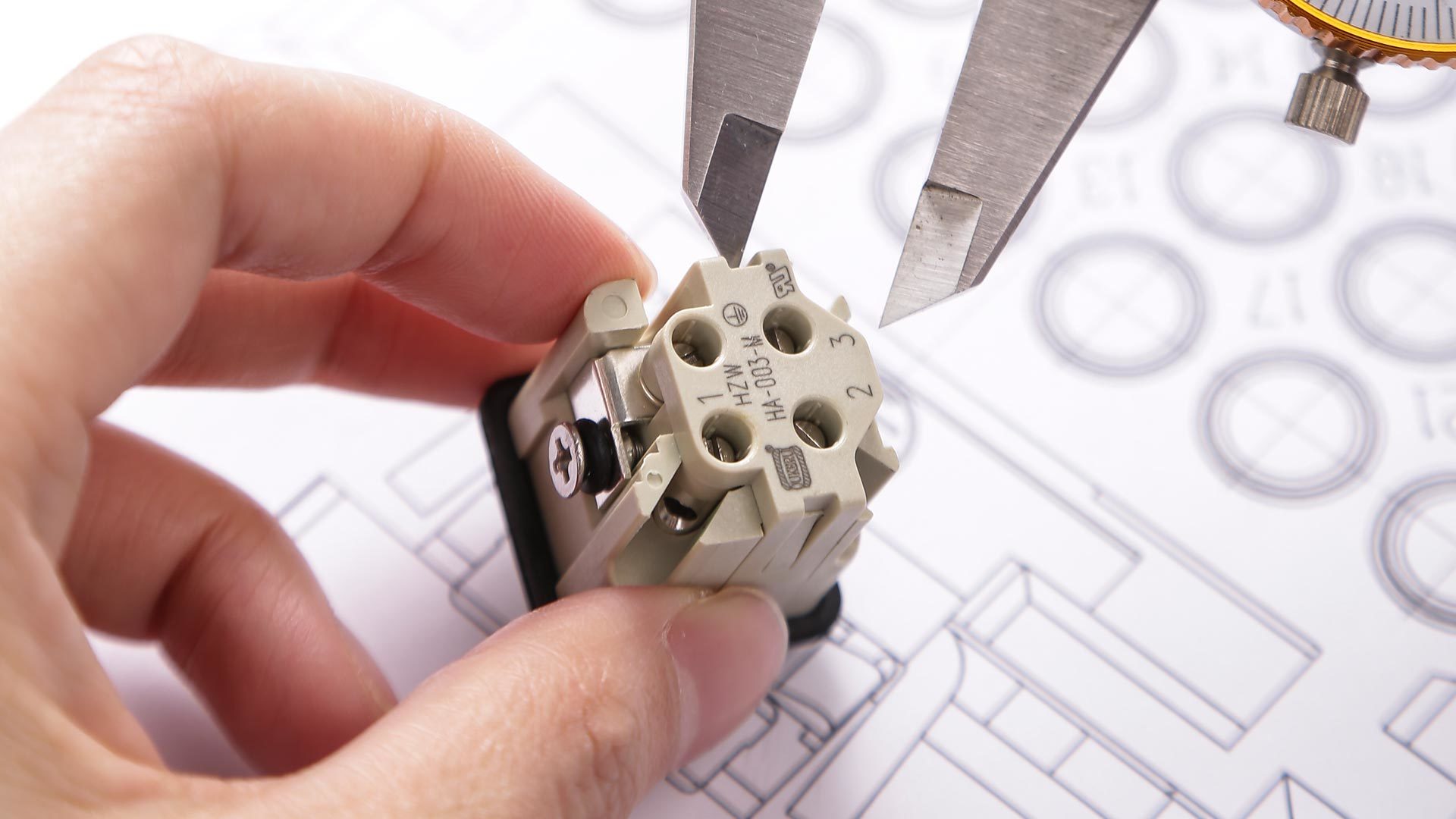

A **rectangular connector housing** serves as the protective casing that houses the internal components of a connector, such as the pins or sockets. These housings not only safeguard the internal elements from environmental factors like dust and moisture but also ensure proper alignment and secure mating of connectors.

The design of rectangular connector housings is optimized for various applications, allowing for easy integration into electronic devices. Their robust construction and engineering ensure they can withstand mechanical stresses, thermal fluctuations, and chemical exposure.

Types of Rectangular Connector Housing

Rectangular connector housings come in numerous types to cater to diverse applications and environments. Here are some common types:

1. **Standard Rectangular Housings**: These are designed for general-purpose applications, offering a balance of performance, size, and cost.

2. **Sealed Rectangular Housings**: Ideal for outdoor or harsh environments, these housings feature seals that protect against moisture, dust, and other contaminants.

3. **Panel-Mount Housings**: Designed for mounting directly onto a panel, these housings provide a stable connection point for cables and wires, commonly used in industrial equipment.

4. **Locking Mechanism Housings**: These housings include integrated locking mechanisms to prevent unintended disconnections, enhancing reliability in critical systems.

5. **High-Density Housings**: For applications requiring a compact design, high-density housings maximize pin count while minimizing space, suitable for advanced electronics.

Benefits of Using Rectangular Connector Housing

1. Enhanced Durability and Protection

The primary function of rectangular connector housings is to protect sensitive internal components and maintain their integrity. The robust materials used, often including plastics like polyamide or polycarbonate, provide resistance to impacts and environmental stressors. This durability significantly extends the lifespan of electronic devices, reducing maintenance costs and downtime.

2. Improved Signal Integrity

Signal integrity is crucial in electronics, especially in high-speed applications. Rectangular connector housings are designed to minimize electromagnetic interference (EMI) and crosstalk between pins. By providing proper shielding and grounding, these housings help ensure stable signal transmission, thus enhancing overall device performance.

3. Versatility in Design

Rectangular connector housings are incredibly versatile, accommodating various pin configurations and spacing. This adaptability allows engineers to select the appropriate housing for specific applications, ranging from consumer electronics to heavy industrial machinery. The availability of multiple sizes and styles also aids in custom applications, making them suitable for unique design requirements.

Applications of Rectangular Connector Housing in Modern Electronics

1. Telecommunications

In the telecommunications industry, reliable connectivity is paramount. Rectangular connector housings are utilized in various communication devices, ensuring stable connections that carry voice and data signals. Their ability to withstand environmental factors while maintaining signal integrity makes them ideal for outdoor applications, including cell towers and satellite systems.

2. Automotive Industry

The automotive industry has witnessed significant advancements in electronic systems, necessitating robust connector solutions. Rectangular connector housings are integral to various automotive applications, including engine control units (ECUs), infotainment systems, and safety features. Their durability ensures that connections remain secure even in harsh operating conditions.

3. Industrial Automation

In industrial automation, rectangular connector housings facilitate reliable connections among machines, sensors, and control systems. The ability to withstand vibrations, dust, and moisture makes these housings suitable for factory environments. Furthermore, their design allows for easy maintenance and replacement, ensuring minimal disruptions in production processes.

4. Medical Devices

Medical devices require stringent performance and safety standards due to their critical applications. Rectangular connector housings are essential for connecting various components in medical equipment, including imaging systems, diagnostic devices, and monitoring equipment. Their reliability and safety features play a crucial role in ensuring patient safety and accurate diagnostics.

Innovations in Rectangular Connector Housing Technology

1. Advanced Materials

Recent advancements in materials science have led to the development of new polymers and composite materials that enhance the durability and performance of rectangular connector housings. These materials offer improved resistance to high temperatures, chemicals, and UV radiation, making them suitable for more demanding applications.

2. Modular Designs

Modular design trends are transforming how rectangular connector housings are constructed. By allowing for interchangeable components, manufacturers can create flexible solutions that can be easily adapted to specific applications. This adaptability leads to cost savings and faster production times, benefiting both manufacturers and end-users.

3. Smart Connectors

The integration of smart technology into rectangular connector housings is paving the way for enhanced functionality. Smart connectors equipped with sensors can monitor connection status, temperature, and environmental conditions. This data can be valuable for predictive maintenance and improving overall system reliability.

Choosing the Right Rectangular Connector Housing for Your Application

Selecting the appropriate rectangular connector housing requires careful consideration of several factors:

1. Environmental Conditions

Identify the environmental conditions the connector will be exposed to, such as temperature extremes, moisture, dust, and chemicals. Choose a housing designed to withstand these factors to ensure long-term reliability.

2. Mechanical Requirements

Consider the mechanical stresses the connector will face, including vibration and impact. Select a housing that offers adequate protection against these forces to maintain connection integrity.

3. Size and Configuration

Evaluate the available space for the connector and the required pin configuration. Opt for a housing that fits within your design constraints while providing the necessary connectivity options.

4. Compliance and Standards

Ensure that the rectangular connector housing meets relevant industry standards and certifications, especially for applications in critical sectors like automotive and medical. Compliance with standards ensures safety and reliability.

FAQs About Rectangular Connector Housing

1. What materials are commonly used for rectangular connector housings?

Rectangular connector housings are typically made from durable plastics such as polyamide, polycarbonate, and thermoplastic elastomers, chosen for their mechanical strength and resistance to environmental factors.

2. How do sealed rectangular connector housings protect against environmental factors?

Sealed housings feature gaskets or O-rings that create a barrier against moisture, dust, and contaminants, ensuring that internal components remain protected in harsh conditions.

3. Can rectangular connector housings be customized for specific applications?

Yes, many manufacturers offer customization options for rectangular connector housings, allowing for tailored sizes, pin configurations, and materials to meet specific application needs.

4. What industries commonly use rectangular connector housings?

Rectangular connector housings are widely used in various industries, including telecommunications, automotive, industrial automation, medical devices, and consumer electronics.

5. How can I ensure optimal performance of rectangular connectors?

To ensure optimal performance, regularly inspect connectors for wear and damage, maintain proper alignment during installation, and adhere to environmental and mechanical specifications.

Conclusion

Rectangular connector housings play a pivotal role in modern electronics, providing the necessary protection, durability, and functionality for reliable connectivity. Their versatility and adaptability across various applications make them indispensable components in a multitude of industries. As technology evolves, innovations in housing materials and designs continue to enhance performance, catering to the growing demands of advanced electronic systems. Understanding their significance and selecting the right housing for your application is crucial for ensuring the longevity and reliability of electronic devices. Embracing the advancements in rectangular connector housing technology will undoubtedly shape the future of connectivity in electronics.

Related news

Introduction to the China International Industry Fair The China International Industry Fair (abbreviated as “China Industry Fair” or “Industry Fair”) is one of China's longest-running national-level industrial exhibitions bearing the “China” designation. Since its inception in 1999,

READ MORE

OUKERUI | New Products New inserts for rectangular connectors

On the basis of the original inserts, we have newly developed straight inserts and cold pressed pins to make the installation of heavy-duty connectors more convenient and more options

READ MORE

The three-day 2025 exhibition Shanghai Electronics Show (electronica China 2025) came to an end yesterday at the Shanghai New International Expo Center. As a benchmark enterprise in the field of heavy-duty connectors, Ningbo OUKERUI Connector Co., Ltd. made a stunning debut in exhibition with multiple innovative products and solutions

READ MORE