The Essential Guide to Choosing the Right 12 Pin Rectangular Connector for Your Project

The Essential Guide to Choosing the Right 12 Pin Rectangular Connector for Your Project Table of Contents 1. Introduction to 12 Pin Rectangular Connectors 2. Types of 12 Pin Rectangular Connectors 2.1 Standard Connectors 2.2 Sealed Connectors 2.3 High-Current Connectors 3. Key Specifications to Consider 3.1 Pin

The Essential Guide to Choosing the Right 12 Pin Rectangular Connector for Your Project

Table of Contents

- 1. Introduction to 12 Pin Rectangular Connectors

- 2. Types of 12 Pin Rectangular Connectors

- 3. Key Specifications to Consider

- 4. Installation and Wiring Techniques

- 5. Common Issues and Troubleshooting

- 6. Maintenance Tips for Longevity

- 7. Applications of 12 Pin Rectangular Connectors

- 8. Conclusion

- 9. FAQs

1. Introduction to 12 Pin Rectangular Connectors

12 pin rectangular connectors are essential components in various electrical applications, enabling reliable connections across multiple circuits. They play a crucial role in industries such as automotive, telecommunications, and consumer electronics. In this guide, we explore the vital aspects of selecting the right connector for your specific project, ensuring you achieve optimal performance and efficiency.

2. Types of 12 Pin Rectangular Connectors

When choosing a 12 pin rectangular connector, understanding the different types available can significantly influence your decision. Each type serves unique purposes and applications.

2.1 Standard Connectors

Standard connectors are commonly used in everyday applications. They typically feature a simple design that supports basic connectivity needs. Ideal for low-power applications, these connectors offer a balance between performance and cost.

2.2 Sealed Connectors

Sealed connectors provide enhanced protection against environmental factors such as moisture, dust, and chemicals. These connectors are crucial in applications where durability and reliability are paramount. They often include gaskets and seals that prevent ingress of contaminants, making them ideal for outdoor and industrial settings.

2.3 High-Current Connectors

High-current connectors are designed to handle significant electrical loads. These connectors are essential in applications that require robust connections, such as power distribution and heavy machinery. Their design often includes larger terminals and reinforced materials to ensure safety and performance.

3. Key Specifications to Consider

Choosing the right 12 pin rectangular connector goes beyond just selecting a type. Various specifications influence the performance and suitability of the connector for your application.

3.1 Pin Configuration

The pin configuration defines how the pins are arranged and utilized within the connector. Understanding the required pin layout for your application is crucial, as it affects compatibility with other components. Look for connectors with configurations that match your circuit design.

3.2 Current Rating

The current rating indicates the maximum amount of electrical current the connector can safely handle. This specification is critical, as exceeding the rated current can lead to overheating and connector failure. Ensure that the current rating of the connector aligns with the demands of your project.

3.3 Voltage Rating

Similar to the current rating, the voltage rating signifies the maximum voltage that the connector can withstand. It is essential for ensuring safe operation within your electrical system. Always select a connector with a voltage rating that exceeds the maximum voltage present in your application.

3.4 Temperature Rating

Temperature ratings indicate the operating temperature range within which the connector can function effectively. Connectors exposed to extreme temperatures may degrade faster, impacting performance and safety. Choose connectors with temperature ratings suitable for the environment in which they will be used.

4. Installation and Wiring Techniques

Proper installation techniques are vital for ensuring the longevity and reliability of your 12 pin rectangular connector. Follow these best practices to achieve optimal results:

- **Preparation:** Before installation, gather all necessary tools and materials, including wire strippers, crimping tools, and heat shrink tubing.

- **Wiring:** Strip the ends of the wires and insert them into the appropriate pins. Ensure a secure connection by crimping or soldering as needed.

- **Securing the Connector:** Once wired, securely attach the connector to its designated mounting point, ensuring a snug fit to prevent movement.

- **Testing:** After installation, conduct tests to verify that the connections are functioning correctly. This may include continuity tests and voltage checks.

5. Common Issues and Troubleshooting

Even with proper installation, issues may arise with 12 pin rectangular connectors. Here are some common problems and their solutions:

- **Intermittent Connections:** If you experience intermittent connectivity, check for loose wires or poorly crimped connections. Re-crimp or re-solder as necessary.

- **Overheating:** Overheating may result from excessive current draw or insufficient cooling. Evaluate the load on the connector and ensure it is within the specified current rating.

- **Corrosion:** If corrosion develops, particularly in sealed connectors, inspect seals and gaskets for damage. Replace any damaged components and use corrosion-resistant materials to prevent future issues.

6. Maintenance Tips for Longevity

To prolong the lifespan of your 12 pin rectangular connectors, consider these maintenance tips:

- **Regular Inspections:** Periodically check connectors for signs of wear, corrosion, or physical damage. Early detection can prevent more significant issues.

- **Cleaning:** Keep connectors clean by using appropriate cleaning solutions. Avoid harsh chemicals that may damage the connector's materials.

- **Proper Storage:** When not in use, store connectors in a dry, cool environment to prevent deterioration from environmental factors.

7. Applications of 12 Pin Rectangular Connectors

12 pin rectangular connectors find applications in various fields, demonstrating their versatility:

- **Automotive:** Used in wiring harnesses for various systems, including lighting, infotainment, and power distribution.

- **Industrial Equipment:** Essential for connecting control panels, sensors, and actuators in machinery.

- **Consumer Electronics:** Commonly found in devices such as computers, printers, and home appliances, facilitating connections between components.

8. Conclusion

Selecting the right 12 pin rectangular connector is pivotal for the success of your electrical project. By understanding the different types, specifications, and installation techniques, you can make informed decisions that enhance performance and reliability. Whether you're working on automotive applications, industrial machinery, or consumer electronics, a well-chosen connector contributes to the overall success of your project.

9. FAQs

What is the difference between standard and sealed connectors?

Standard connectors are suitable for basic applications, while sealed connectors provide protection against environmental factors, making them ideal for harsh conditions.

How do I determine the correct current rating for my connector?

Evaluate the electrical load requirements of your application and ensure that the connector's current rating meets or exceeds these demands.

Can I use a lower voltage-rated connector in a higher voltage application?

No, using a lower voltage-rated connector can lead to failure and safety hazards. Always select a connector rated for higher voltages than your application requires.

What maintenance is required for 12 pin connectors?

Regular inspections, cleaning, and proper storage are essential for maintaining the integrity and performance of your connectors.

Where can I purchase high-quality 12 pin rectangular connectors?

High-quality connectors can be purchased from reputable electronic component suppliers, both online and in physical stores. Look for suppliers that provide specifications and customer support.

Related news

Introduction to the China International Industry Fair The China International Industry Fair (abbreviated as “China Industry Fair” or “Industry Fair”) is one of China's longest-running national-level industrial exhibitions bearing the “China” designation. Since its inception in 1999,

READ MORE

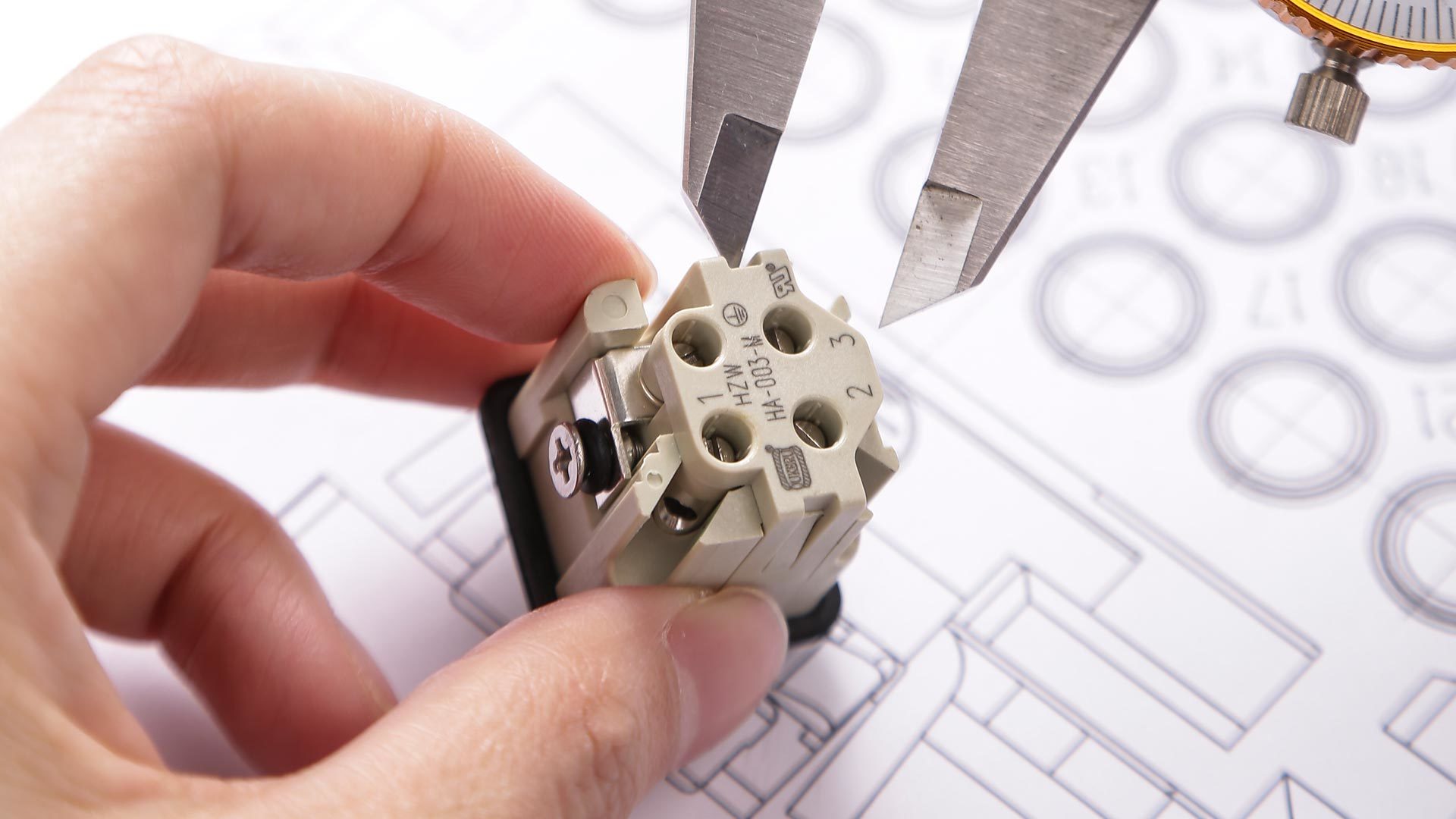

OUKERUI | New Products New inserts for rectangular connectors

On the basis of the original inserts, we have newly developed straight inserts and cold pressed pins to make the installation of heavy-duty connectors more convenient and more options

READ MORE

The three-day 2025 exhibition Shanghai Electronics Show (electronica China 2025) came to an end yesterday at the Shanghai New International Expo Center. As a benchmark enterprise in the field of heavy-duty connectors, Ningbo OUKERUI Connector Co., Ltd. made a stunning debut in exhibition with multiple innovative products and solutions

READ MORE